Buildings require an adequate ventilation system to maintain right indoor air quality which is safe and healthy for the inhabitants.

The quality of indoor air can be deteriorated due to many factors that can be external and internal as well, this makes the building unhealthy for the occupier. To ensure a healthy environment inside the building, initially during the design stage proper attention and study needs to be done with regards to the location and functionality of the building. Post construction, once occupied, regular monitoring for the IAQ is a must. A high standard IAQ requires the right air change rate to be maintained, this calls for filtration and treatment of the incoming fresh air from the outside environment.

To ensure the building continuously operates at high IAQ standards, misconception is, it requires high initial outlay and high operating cost.

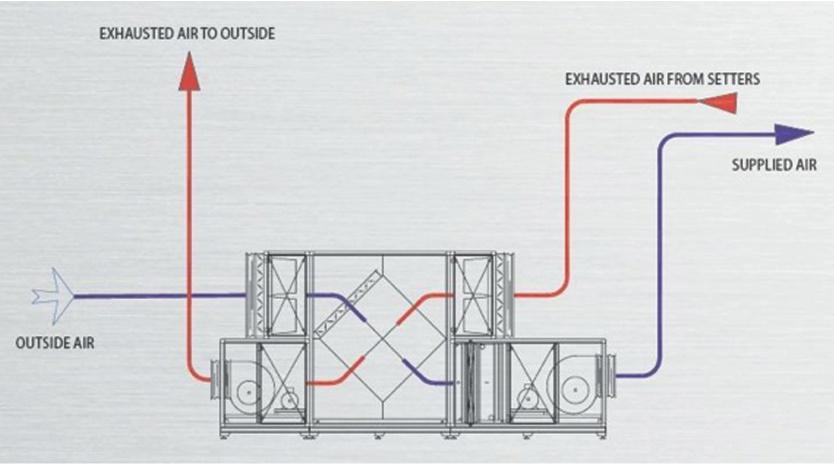

Air to Air Energy Recovery system incorporated inside the air handling or air movement path or in system for recovering the energy from exhaust air to incoming fresh Incoming air can clear all misconception. The long term Impact of the heat recovery system considering the end user interest in mind over the building life cycle cost is the right perspective for building owners.

The Heat Recovery System can be selected based on either recovering sensible energy, or sensible + latent energy, permissible cross contamination considering Covid-19 guidelines and operating and maintenance cost. Today HVAC system designers have a wide choice to choose Heat Recovery solutions.

When the building has 100 percent fresh Air Load, the functionality calls for ‘No Cross-Contamination’ requirement, the right choice will be to go in for ‘Cross Flow Type Plate Heat Exchanger’ which is a very simple no maintenance component inside the air treatment unit, which will take care of the sensible energy recovery of the Incoming fresh air. Similarly HEAT PIPE, be it Vertical / Horizontal Heat Pipe can be used towards energy recovery without compromising on IAQ requirements. Wrap around Heat Pipe heat exchanger can be a good solution to dehumidification and humidity control.

Cross Flow Type, Air-to-Air heat exchanger and application areas

Air-to-air heat exchangers are used both in heat and energy recovery in ventilation applications and in closed loop cooling solutions for thermal management. There are two categories of air-to-air heat exchangers, rotary and plate heat exchangers.

A plate heat exchanger is a type of energy recovery heat exchanger positioned within the supply and exhaust air streams of an air-handling system.

A plate heat exchanger works in a rather straightforward process. Two neighbouring aluminium plates create channels for the air to pass through. The supply air passes on one side of the plate and the exhaust air on the other side. The heat in the exhaust air is transferred through the plate from the warmer air to the colder air.

A very important parameter for the performance of a plate heat exchanger is the spacing between the plates. A narrow channel leads to high-pressure drop but also to high efficiency. The latter means that more heat is transferred to the cold side. If a lower pressure drop is required, it is better to use a higher channel spacing. The tradeoff is lower efficiency.

Usually, the exhaust air is contaminated with humidity and pollutants, but with a plate heat exchanger, airflows never mix, leaving the supply air fresh and clean. To avoid leakage and contamination, Heatex plate heat exchangers are constructed with a double sealing concept. This means both glueing and a mechanical fold.

To protect the aluminium from harmful substances or corrosive environments it’s recommended to coat the plates with epoxy and paint both end plates and profiles.

The two most common types of plate air to air heat exchangers are cross flow and counter flow heat exchangers. In a crossflow heat exchanger, the cold and the warm air flow perpendicular to each other. In counterflow exchangers, the two airstreams flow in opposite directions to one.

Certified performance

HEATEX products always comply with standards, always perform according to (or even exceed) codes and specifications. Heatex holds several certifications covering product and operation quality worldwide, e.g., Eurovent, AHRI, and TüvSüd. Our products are field-tested and designed to comply with all relevant building codes and regulations. We frequently send our products to independent labs worldwide for inspection and we have our own in-house test rig to regularly evaluate product performance.

For more Info, visit: heatex.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.