Mandar Vaijanapurkar, Head – Sales & Service, Danfoss Drives, India Region, Danfoss asserts that smart AHUs significantly reduce energy consumption and decrease modern buildings’ carbon footprint.

What essential AHU features enhance ventilation system performance?

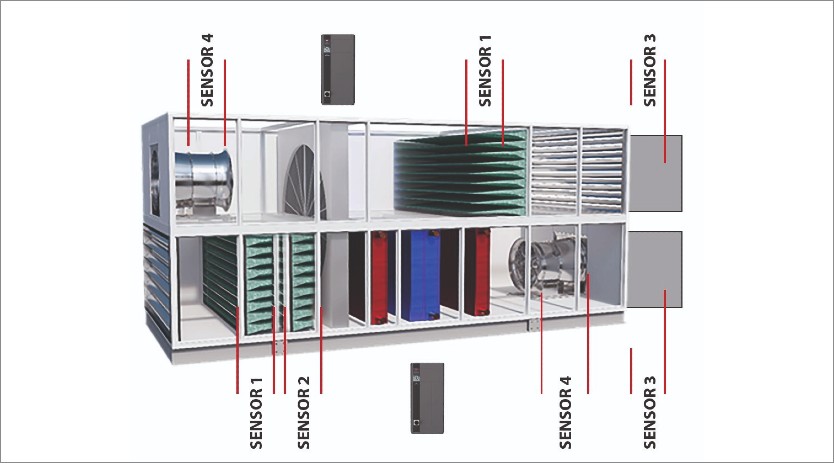

The primary role of an Air Handling Unit (AHU) is to take in outdoor air, adjust its temperature, and supply it with fresh air within a building. Depending on the desired indoor temperature, the conditioned air is either heated or cooled using a recovery unit or heating coil. Various components within the AHU, such as the cooling coil, Variable Frequency Drives (VFDs), filters, heat recovery system, humidification and dehumidification elements, dampers, fans, blowers, as well as sensors and control systems, impact its ventilation performance.

Achieving the most accurate exhaust air temperature from the AHU hinges on precise water flow control into the heat exchangers. These are responsible for heating or cooling the incoming air. Variable flow systems are usually used for this purpose. Both during full and partial load conditions, Pressure Independent Balancing and Control Valves (PICV) yield optimal outcomes. Under full load, these valves function as automatic flow limiters by setting the required flow rate. When the load is partial, an actuator adjusts the flow. This prevents the heating or cooling source from exceeding capacity, boosting energy efficiency.

What key parameters to consider for designing AHU for a specific space?

The design of an AHU within an HVAC system is contingent on project-specific needs. Also, the designer’s approach, experience level, code adherence, and design communication are intended through plans and specifications.

Several factors shape AHU design, including the project’s purpose, efficiency, maintenance needs, building size, location, and cost. Generally, building area and climate are key factors. However, essential AHU design principles include determining the air volume (in Cubic Feet per Minute or CFM) required for effective heat removal.

This can be calculated using the formula: Q = 1.1 x CFM x ΔT, where Q represents sensible load, ΔT is the temperature difference between return and supply air, and CFM signifies the air volume needed to maintain the desired temperature. Factor 1.1 accommodates atmospheric pressure, which is suitable for sea-level operations. AHU classification results from the above formula. For a constant space load Q, either the CFM can be adjusted, or ΔT can be modified to accommodate changes in load. When CFM remains constant, it’s a Constant Volume (CV) AHU. If CFM changes to match the load, it becomes a Variable Air Volume (VAV) system.

The AHU’s cooling coil design affects performance. It hinges on air velocity across heat exchange surfaces. Higher velocity means a smaller coil, higher pressure drop, and more powerful fans. Conversely, lower velocity increases coil size, but pressure drop is lower and reduces fan energy needs. HVAC designers strive to deliver a cost-effective system that meets comfort needs; while minimising maintenance and energy expenses. The main concerns are indoor air quality (IAQ), energy efficiency, and occupant comfort.

How do smart AHUs help in reducing carbon footprint in large spaces?

Digitized AHUs incorporate sensors, data analysis, automation, and connectivity technologies to enhance efficiency, control, and overall performance. These digitised AHUs are equipped with integrated controls and are linked to automation systems through remote connections. This advanced feature enables the monitoring all AHU parameters, including temperature, humidity, airflow, and filter status. The utilisation of such technology leads to substantial savings in thermal and electrical energy and operational and maintenance costs. These energy-efficient AHUs deliver top-notch air quality and a comfortable indoor environment. This can be conveniently accessed remotely using smartphones and computers, all at an optimised cost.

High-capacity cooling solutions are essential in sectors like commercial spaces and the hospitality industry. Hence, the demand for powerful and energy-efficient equipment is crucial. Smart AHUs play a significant role in reducing energy consumption and decreasing the carbon footprint of modern buildings. Danfoss AC Drives help in achieving energy efficiency without compromising the safety and comfort of building occupants. These drives help adhere to increasingly stringent efficiency standards while ensuring perfect indoor air quality and safety. They achieve this by minimising the potential spread of airborne infections and maintaining thermal comfort for building occupants and staff while effectively addressing the challenge of high energy costs.

How does AHUs fan system determine its energy efficiency and performance?

The fan system within an AHU plays a pivotal role in determining its performance and energy efficiency. The choice of fan design and technology is crucial. The conventional AHUs employ belt-driven centrifugal fans with around 50-60 percent WTA efficiency and IE4 motors. So, there has been a recent shift towards plug fans with higher efficiency ranging from 63-68% WTA. The emerging trend involves EC (Electronically Communicated) fans – plug fans powered by EC motors, achieving even better efficiency of around 65-70 percent with IE4 or IE5 motors. The market is exploring Axial fans with the EC+ solution, boasting exceptional efficiency exceeding 80 percent with IE5 motors and efficient drives.

Maintaining an optimal temperature difference between supply and return air in heating and cooling modes is critical for achieving efficiency. To maximise overall savings, it’s vital to synchronise the speed of the fan, pump, and chiller and modulate the flow to maintain the desired return temperature differential.

Danfoss AC drives designed for HVAC applications offer variable control over fan speed. It ensures that fan speed and chilled water flow rates are proportionally adjusted. Additionally, the AB-QM pressure-independent control valve prevents any overflow. It ensures that the coolant doesn’t rush through the heat exchanger too quickly, thus allowing for effective heat absorption.

What factors are considered necessary to maintain AHUs to ensure optimal operation?

AHUs constitute a crucial element within a building’s HVAC system, demanding maintenance and care. Neglecting AHU upkeep leads to elevated energy expenses, increased indoor pollutants, and insufficient thermal comfort for occupants. AHUs are often overlooked due to their straightforward functionality of delivering cooled air, even if degraded. The consequences of neglecting AHU maintenance are significant, necessitating a shift in focus by building maintenance planners and staff. Prioritising AHU maintenance and operation can enhance indoor air quality for occupants. It lowers operational expenses for building owners through reduced energy consumption in AHU operations.

Several other areas require equally vital maintenance attention. These include cleaning filters, assessing motor vibration levels, inspecting filter damage, checking belt tension, and measuring filter pressure differentials and noise levels. It also includes evaluating CFM measurements, air leakage, ensuring proper damper function, validating bypass valve operation, calibrating sensors, and maintaining general hygiene and upkeep.

What key challenges associated with AHUs need to be diagnosed and resolved?

Effectively diagnosing and resolving AHU challenges follows a structured approach. Common challenges are inadequate airflow, uneven air dispersion, temperature or humidity fluctuations, excessive noise or vibrations, air leakage, indoor air quality concerns, obstructed filters and ducts, and sensor and control malfunctions. These problems are remedied through routine maintenance and considering factors for optimal performance.

The fault detection system comprises numerous rules to assess wasted energy, user discomfort, and reduced equipment lifespan. This aids in categorising detected faults based on their severity. This approach is applied to actual HVAC units, with an assessment to pinpoint the root causes. The detection tool identifies faults by analysing a diverse dataset of measurements collected during the standard operation of numerous HVAC units. Eliminating operating faults means energy savings of several thousand dollars annually.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.