This article explores how implementing battery energy storage systems (BESS) has revolutionised worldwide electricity generation and consumption practices. In this context, cooling systems play a pivotal role as enabling technologies for BESS, ensuring the essential thermal stability required for optimal battery performance, durability, and safety.

This article explores how implementing battery energy storage systems (BESS) has revolutionised worldwide electricity generation and consumption practices. In this context, cooling systems play a pivotal role as enabling technologies for BESS, ensuring the essential thermal stability required for optimal battery performance, durability, and safety.

The global adoption of battery energy storage systems (BESS) acts as an enabling technology for the radical transformation of how the world generates and consumes electricity. This shift entails moving away from a centralised grid model reliant on one-way power flow from fossil fuel plants to alternative methods that prioritise cleanliness, renewable sources, flexibility, resilience, distribution, and affordability.

Hot, but not too hot

The rapid expansion of the electric vehicle industry has accelerated the adoption of stationary battery storage, supported by significant investments in battery research and development, as well as advancements in manufacturing efficiency and scalability. The market for BESS is projected to grow at a CAGR of 30 percent from 2023-2033, according to IDTechEx. The global cumulative stationary battery storage capacity is expected to reach 2 TWh within ten years.

However, the hot market for BESS is challenged by the fact that electrochemical energy storage is notoriously vulnerable to overheating. From phones to EVs to large BESS systems, overheating of batteries risks sudden fire and explosion, causing degraded performance and shortened lifetime. Therefore, cooling systems are a critical enabling technology for BESS, providing the thermal stability crucial for battery performance, durability, and safety.

What’s driving the rapid adoption of BESS?

The growth of solar and wind-generated renewable energy is one of the drivers of the rapid adoption of battery energy storage systems. BESS complements these renewable sources by buffering and time-shifting and facilitating remote and off-grid use cases.

Renewable energy is not the only driver. Large-scale BESS installations are also incorporated into electrical grid networks to balance energy demand and resilience to grid failure. For example, the Pillswood project in Yorkshire, UK, went live in November with a 98MW/196MWh BESS facility, enough capacity to power 300,000 homes for two hours.

The residential sector is experiencing significant growth as more consumers strive for energy self-sufficiency in light of extensive grid failures and escalating energy costs. Additionally, a growing demand for clean energy solutions involves integrating solar power, electric vehicles (EVs), and heat pumps.

The residential market is expanding rapidly as consumers seek energy independence due to extensive grid outages and escalating energy prices. Additionally, a growing demand for clean energy solutions involves integrating solar power, electric vehicles (EVs), and heat pumps. (BESS systems have been installed in 31,000 homes in Australia, and 100,000 in Germany, and the California Public Utilities Commission (CPUC) is offering $1 billion in rebates for residential battery storage through 2024).

Businesses also install battery energy storage systems for backup power and more economical operation. These “behind-the-meter” (BTM) systems facilitate energy time-shift arbitrage, in conjunction with solar and wind, to manage and profit from fluctuations in the pricing of grid electricity. BESS is a cost-effective method of powering large dynamic loads, such as big compressors, motors, and generators, without building electricity infrastructure and grid connections to accommodate load spikes and peak demand.

Evolving battery technology

Constant advancements are being made in battery technologies, including developing new architectures and chemistries. However, Lithium-Ion batteries remain the predominant choice for energy storage systems. This is primarily due to their decreasing costs, improved performance, lightweight design, and space-efficient nature, resulting in higher energy density than other battery types.

Nevertheless, alternative battery technologies are emerging as viable options. For example, Sodium-sulfur (Na-S) batteries offer high energy, power density, and long lifespan. However, it is important to note that Na-S batteries have certain hazards, including flammability and explosiveness. As a result, they are more suitable for stand-alone renewable energy storage applications, where these risks can be isolated and managed effectively.

Image

Liquid electrolyte-based flow batteries are gaining traction in the market, especially in large-scale applications, as they can store energy efficiently. They offer a long lifespan, fast response time, high scalability, and very low fire risk, but they provide relatively low energy capability and slow charging/discharging rate. Lithium-ion will continue to be the most common BESS technology for the foreseeable future. More than 90 percent of large-scale BESS systems in the US use lithium-ion batteries, according to the US Energy Information Administration, a penetration rate that is typical around the globe.

Thermal stability and uniform temperature

Generally, it is best to keep batteries at a moderate, consistent temperature to ensure optimal performance and longevity. Exposure to extreme temperatures, either hot or cold, can damage batteries and cause hazardous events.

The specific temperature range that batteries require to operate safely can vary depending on the type of battery and its design. The safe operating temperature range is typically between -20°C and 60°C for lithium-ion batteries, between -20°C and 45°C for nickel-metal hydride batteries, and between -15°C and 50°C lead-acid batteries. It is important to carefully consult the manufacturer’s specifications for the specific battery type to determine its precise, safe operating temperature range.

According to the US National Renewable Energy Laboratory, the optimal temperature range for Lithium-Ion is between 15 °C and 35 °C. Research shows that an ambient temperature of about 20°C or slightly below (“room temperature”) is ideal for Lithium-Ion batteries. If a battery operates at 30°C, it’s lifetime is reduced by 20 percent. At 40°C, the losses in lifetime approach 40 percent, and if batteries are charged and discharged at 45°C, the lifetime is only half of what can be expected at 20°C.

Thermal stability is critical to performance, longevity, and safety. Also equally important is maintaining uniform temperature throughout the system. Avoiding hot spots is crucial to preventing damage and mitigating the risk of triggering a chain reaction that leads to catastrophic thermal runaway.

Internal and external causes of overheating

Multiple factors can contribute to overheating.

Applications: Applications requiring rapid charging/discharging are referred to as having a high C-rate, defined as the charging or discharging current divided by the capacity (the amount of energy the battery can hold). With a high C-rate and frequent cycling, internal resistances to the higher currents generate heat.

Ambient temperature: High ambient temperature also damages batteries in several ways. One problem is that elevated temperatures lead to an increased rate of side reactions causing attrition of active material and resulting in a build-up of resistance at the electrode surface. Operating lithium-ion batteries at high temperatures will accelerate ageing and lead to performance degradation. Two types of ageing occur in combination due to lithium-ion batteries’ complex composition and working process: cycle ageing occurs while charging and discharging, and calendar ageing occurs over time while a battery is inactive.

Paradoxically, low ambient temperatures can cause more problems with internal overheating than high ambient temperatures. One reason is that cold temperatures can result in viscosity changes in the electrolyte, leading to sluggish ion transport, resulting in higher resistance and heat generation.

Designing an optimal cooling solution

Various thermal management solutions are available, and the choice of the optimal solution is informed by the C-rate of the application, and the environmental conditions, among other factors. At the high end, the most demanding thermal management applications, such as large-scale BESS installation and high C-rate applications, require active liquid cooling. On the other end of the spectrum, smaller installations with low C-rate applications can be safely and efficiently operated at peak performance with air cooling.

Over the years, thermal management technologies have undergone significant advancements to meet the ever-growing cooling demands in the electrotechnical industry. For instance, Pfannenberg, a renowned manufacturer of thermal management products, initiated the development of innovative solutions in the 1950s, such as the pioneering filter fan, to regulate the temperature within electrical enclosures. Over the decades, Pfannenberg expanded its product range to include air and liquid cooling solutions for manufacturing processes and data centres. These diverse and well-established thermal management solutions effectively cater to the performance requirements and environmental conditions of a diverse range of BESS applications.

Liquid cooling

Active water cooling is the best thermal management method to improve BESS performance. Liquid cooling is highly effective at dissipating large amounts of heat and maintaining uniform temperatures throughout the battery pack, allowing BESS designs to achieve higher energy density and safely support high C-rate applications.

thermal

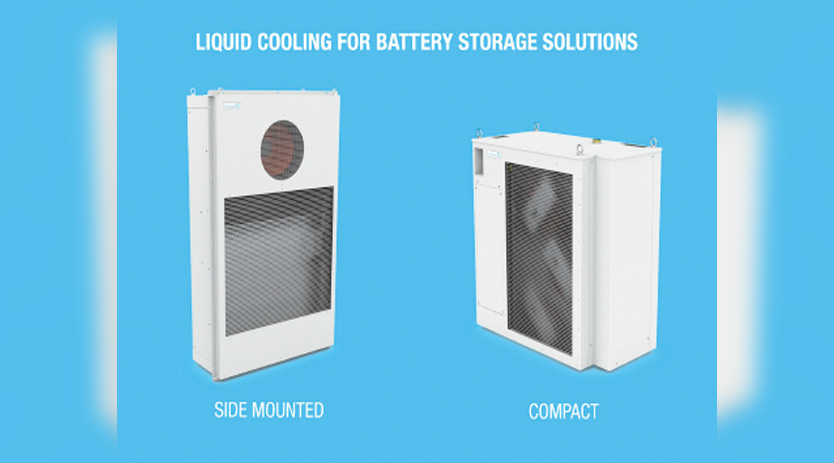

As the BESS market evolves with a wide diversity of designs and applications, multiple versions of chillers are available to optimise the layout of the cooling system. For example, Pfannenberg offers two layout options. A stand-alone chiller can be placed inside the BESS. Each unit provides up to 12kW of cooling, and multiple units can be combined for easy scalability to support the highest cooling load requirements. Alternatively, a compact version is designed to be mounted outdoors on the cabinet door for a small footprint that allows easy integration inside battery cabinets and enclosures.

Both solutions safely operate between -25 and +50°C and offer up to 800 V DC power supply to directly connect with the battery system, all while not needing any power conversion. The solutions offer CE/UL certifications for worldwide operations and high energy efficiency and reliability with their EC brushless fans and microchannel condensers. An inverter pump and compressor also provide better energy management during charge and discharge, while an internal heater preserves battery life in winter by maintaining a stable minimum temperature.

Air cooling

At the other end of the spectrum, air cooling systems provide a cost-effective cooling solution for smaller stationary energy storage systems operating at a relatively low C-rate.

thermal

For example, Pfannenberg’s DTS Cooling Unit seals out the ambient air and then cools and re-circulates clean, cool air through the enclosure. The closed-loop design isolates the external ambient air from the internally conditioned air eliminating the risk of contaminants entering the cabinet. The hermetically sealed compressor guarantees 100 percent cooling capacity efficiency.

In applications where the cooling load is relatively low, and the surrounding air temperature is consistently lower than the desired enclosure temperature, filter fans offer a highly economical solution. These fans utilise natural convection to circulate the air and dissipate heat, providing an effective and cost-efficient cooling method.

The crucial role of cooling technology

Energy storage is of paramount importance in the transition towards a carbon-neutral society. It enables the integration of renewable energy sources into electricity systems and enhances overall energy efficiency by effectively balancing energy production and consumption. In this context, battery energy storage systems (BESS) have become indispensable.

To ensure optimal performance, longevity, and safety of BESS, cooling systems play a critical role in maintaining thermal stability. When implemented effectively, these cooling systems help mitigate battery degradation and potential damage, thus reducing operational downtime.

Authored by: Adam Wells, Solutions Engineer, Pfannenberg USA, Inc.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.