Mitsubishi technology achieves more uniform room-wide temperatures and reduces uncomfortably strong airflows.

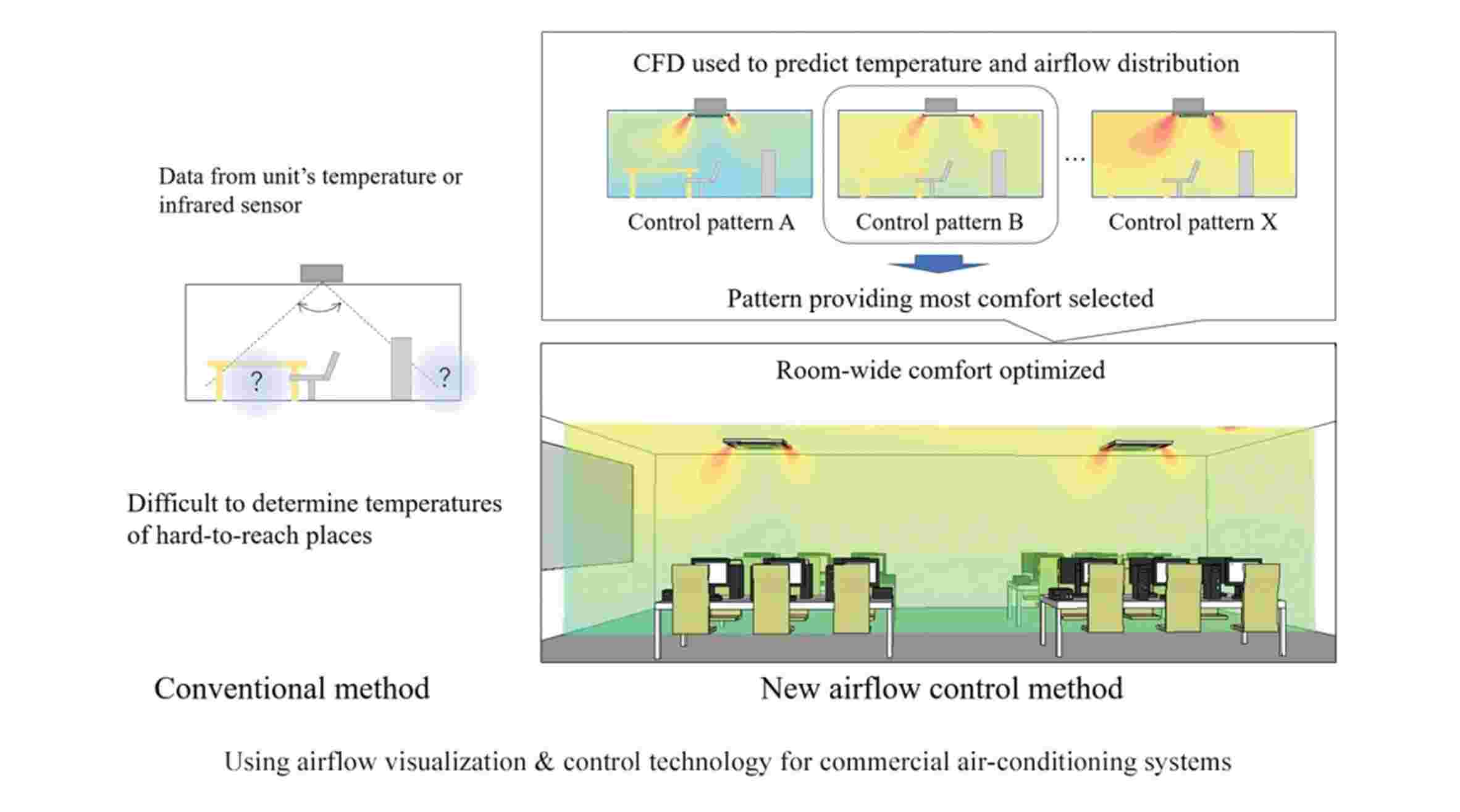

Mitsubishi Electric Corporation developed a new airflow control technology that both visualises and analyses airflow from air-conditioning systems and temperature distribution for optimised room-wide comfort. The technology predicts airflows and temperatures, which vary according to the room shape and air-conditioning system layout, to determine how to minimise uneven temperatures and discomfort due to excessively strong airflow. As such, the technology contributes both to occupant satisfaction and to building asset value. Mitsubishi Electric also expects to use its new solution to advise building owners and designers on how to enhance indoor layouts for increased comfort.

In recent years, due to the impact of Covid and other factors, there has been an increasing emphasis on the healthfulness and comfort of indoor spaces, including ventilation. So far, however, it has been difficult to use built-in sensors of AC units to collect data on airflow due to great variations in room and air-conditioning system layouts.

Details of the new technology were delivered at the 55th Japanese Joint Conference on Air-conditioning and Refrigeration, at the Etchujima Campus of Tokyo University of Marine Science and Technology on April 20-21.

Predicts airflow and temperature distribution to determine optimal conditions

- Computational fluid dynamics (CFD) is used to predict airflow and temperature distribution in out of-the-way places, such as under desks or behind partitions, or due to other A/C units nearby.

- Using airflow and temperature distribution as comfort indices, ideal airflow angles and volumes are automatically determined and controlled for optimised roomwide comfort.

Conventionally, indoor airflow is controlled independently by each A/C unit using data from its builtin sensors. But depending on the room layout and/or position of each unit, airflow may not reach areas such as corners. Also, the operation of adjacent units can disrupt intended airflows. Mitsubishi Electric’s new technology, however, generates three-dimensional models using information on room and air-conditioning system layouts, and it also predicts airflow and temperature distribution using CFD analysis to test various conditions, including airflow angles/volumes and heat levels. From CFD analysis results, the technology selects the most ideal conditions and controls the A/C system’s actual operation.

As a result, the technology enables airflow to be optimized, including when multiple A/C units are operating in the same room. Airflow analysis enables the prediction of complex airflow and temperature distribution, which is used to determine ideal airflow volume and direction required to maximize room-wide comfort, including in spaces near the floor and behind obstacles. As shown in Fig. 1, collisions between diagonal airflows are avoided and conditioned air reaches all corners of the room relatively uniformly. In areas by windows, where the floor temperature takes a long time to rise due to cold air from coming through the windows, the time required to close the temperature gap between 0.1 m and 1.7 m above the floor by at least 3°C was sharply reduced to just 3 minutes, compared to 163 minutes conventionally, in tests conducted by Mitsubishi Electric between 8:00 and 17:00 at the company’s net Zero Energy Building (ZEB) technology-demonstration facility, SUSTIE.

Generates models to visualize airflow, temperature distribution and ventilation effects

- Data required for airflow analysis, such as the locations of walls, floors, columns and A/C equipment, is extracted from building-information modeling (BIM) data to generate three-dimensional models.

- Airflow analysis is performed by virtually testing models incorporating different furniture, indoor units and ventilation system layouts to visualize airflow, temperature-distribution and ventilation effects.

Constructing indoor models for CFD requires time and effort, and experts capable of analyzing the resulting information are limited. In response, Mitsubishi Electric has developed technology to lighten this workload and to simplify the processes of determining ideal settings as well as visualize and display the results intuitively. The solution collects information on room, indoor units and ventilation system layouts using BIM data (method for centrally managing and utilizing building lifecycle information) and then generates three-dimensional room models for airflow analysis. Room, indoor units and ventilation system layouts can be changed easily on-screen and the model numbers of specific Mitsubishi Electric A/C systems can be entered from a database. Results of different patterns can be compared using airflow animations and color-coded diagrams of temperature contours, CO2 concentration levels and times required for air from vents to reach specific areas. As an example, in Fig. 2 below, the solution was used to determine that Layout 2, which positioned output vents in the room center and intake vents by the windows and in the hallway, allowed air to be distributed more uniformly than in the case of Layout 1. Moreover, this highly effective layout was achieved without the involvement airflow-analysis experts

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.