Iqbal Singh Anand, Chairman of ALP group, discusses the insulation provided for a wide range of products and acoustic technology for commercial and residential use.

How does ALP’s elastomeric foam technology provide a competitive edge in the Indian automotive market as a leading converter of sealing systems?

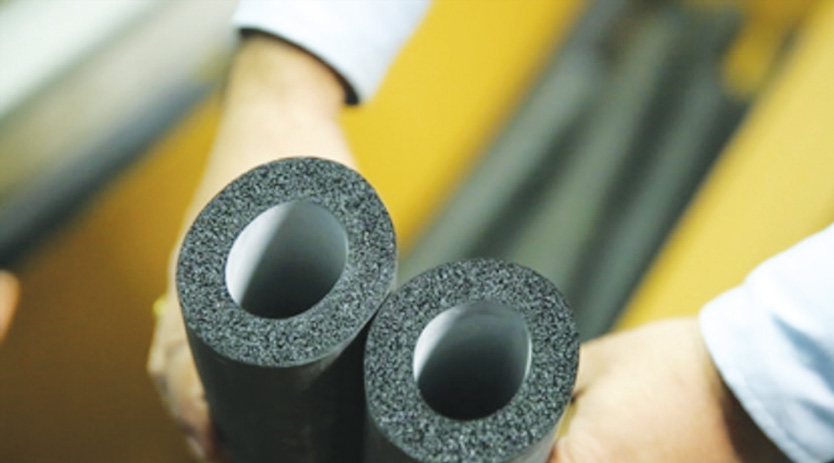

ALP, India’s largest purchaser of EPDM products, is the automotive industry’s primary supplier of sealing systems. We have a widespread presence with seven facilities in India, catering to all major automakers such as Maruti Suzuki, Tata, Mahindra, and Nissan. Our rubber business is developing its own technology for the foaming industry, elastomeric foam. This construction project was initiated in 2008, and we have since become the industry leader. In addition, we have partnered with Aerofl ex, a Thai company that is a global leader in EPDM. We are the sole producers of EPDM and nitrile insulation in India.

What is the scope of ALP’s operations in India and abroad, and how has the recent establishment of ALP Polymer Park contributed to its growth?

The company operates large manufacturing plants and generates annual revenue of $250 million. It comprises three entities: ALP Overseas, ALP Aerofl ex, and the largest, ALP Nishikawa. There are six locations in India, including two in Sanand and one each in Nasik, Largo Punjab, and Gurgaon. Recently, we established ALP Polymer Park, a 50-acre industrial polymer park near Delhi. The company also has installation facilities in Rudrapur and fi ve international offices in Melbourne, South Africa, Düsseldorf, Barcelona, and New York, where our products are sold.

What are some recent innovations and advancements made by ALP in thermal insulation, air conditioning, and solar technology?

At ALP, we are dedicated to pursuing excellence and innovation and are recognized as one of India’s leading innovation centres. We have obtained NABL accreditation and have multiple facilities for introducing new products. Recently, we have made advancements in thermal insulation and air conditioning technology, including developing twin drive tubes suitable for the solar industry. Furthermore, we have started incorporating PVC and UPVC claddings in our products.

How does ALP’s soundproofing sheet effectively reduce noise?

ALP’s soundproofing sheet weighs 1800 kilograms per square meter and effectively dampens sound when used with the demo boss box. Our five-star hotels use our products to block noise from loud banquets and discos. Moreover, we use the echo sound acoustics variation in the duct to reduce air noise.

How has ALP designed its product line to cater specifically to Indian customers?

ALP’s product line was developed specifically for Indian consumers and is entirely manufactured in India. Our floor deadening sheets prevent noise transmission between floors, while our anti-fatigue mats are designed for the IT sector to reduce exhaustion and knee pain from standing all day. We have also created EPDM granules for play fields, which provide a high-quality track experience comparable to the best tracks in the world. Our primary objective is to produce domestic products that meet international standards.

How does ALP insulate cold liquid lines and storage, and what is its speciality in plastic extrusions for doors and refrigerator seals?

We provide comprehensive insulation solutions for cold liquid lines and cold storage and a range of plastic extrusions for doors, specialising in refrigerator seals. We are a top supplier of refrigerator industry aftermarket goods, exporting to both the US and Australia.

How can the HVAC industry sector improve ducting insulation technology?

In the HVAC sector, insulation is crucial, and it’s essential to take it seriously. Nitrile is commonly used in the industry but is poisonous and can release lethal gases during a fire. To avoid this, EPDM is recommended because it is UV-resistant, anti-microbial, non-corrosive, and fire-safe. However, the cost is a significant factor in this sector, and some people try to cut corners, which can harm humans. Insulation should be a minimum portion of a building’s overall construction.

What are some advancements in insulation technology, specifically in terms of products offered by ALP?

ALP has introduced two novel products: APDM, which is naturally anti-microbial, fi reproof, and UV resistant, and fiber duct, which is fire resistant and cannot catch fire. These products are being considered as part of ALP’s insulation line.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.