Reducing the risk of transmission of infectious aerosol by enhancing Air Conditioning Systems

As the world fights to come out of the grip of Covid-19 pandemic, many things are changing in the ‘new normal’. As we gradually started operations in our offices, the concern regarding the spread of the virus via the air conditioning system was looming over our heads.

HVAC (Heating, Ventilation and Air Conditioning) systems can have a major effect on the transmission of infected microscopic airborne particles and contaminated aerosol droplets. If the Air Conditioning is not maintained well and is not enhanced for post COVID scenario, it may lead to spreading the infection further.

Considering this, we have devised a whole new approach to the existing Air Conditioning system in the new normal. Meticulous planning has been done for the air inside offices post-opening as providing safe air inside closed spaces is a big challenge post COVID.

We extracted, examined and analysed information pertaining to the behaviour and transmission of the virus and came up with a unique, innovative solution to give a whole new improvement to the existing Air Conditioning systems in use.

According to McKinsey (Can HVAC systems help prevent the transmission of COVID-19?) research and analysis, Filtration, Irradiation, Thermal heating and Ionisation are the various techniques to improve Indoor Air Quality. Of these, Air Filtration is the most common and preferred technique, followed by Irradiation.

A thorough benchmarking for solutions to control the transmission of infectious aerosols in indoor environments helped us to take initiatives to retrofit the central air-conditioning systems:

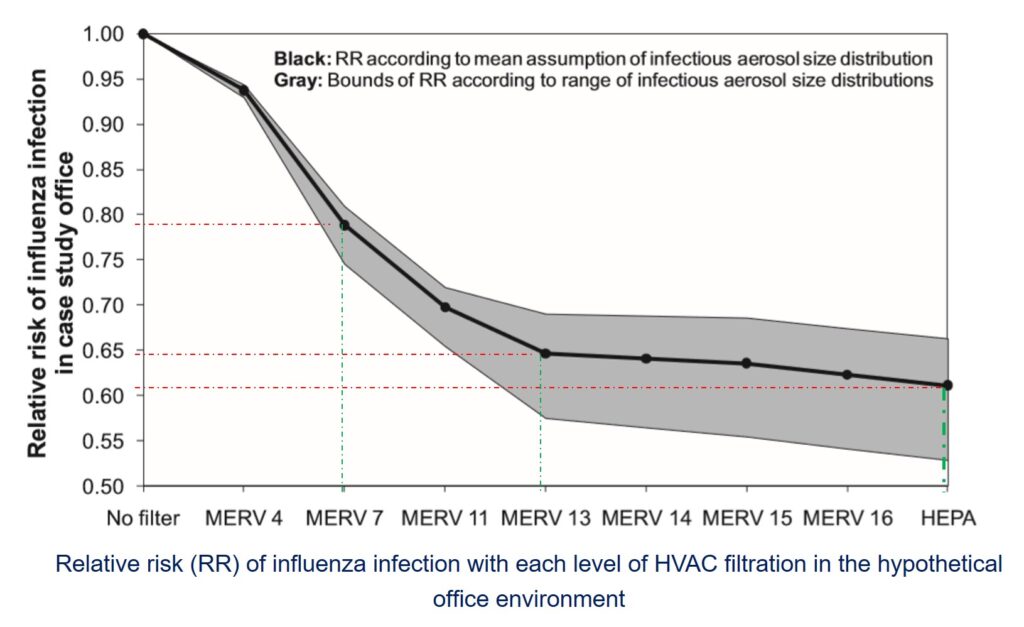

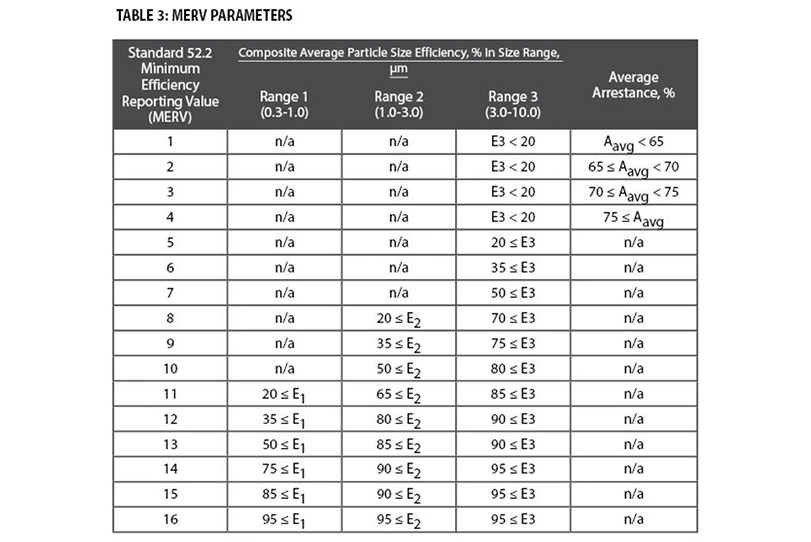

Improvisation in air filtration by adding higher grade filters (MERV 13) to limit the particles concentration

The graph above shows that MERV 13 has nearly 14% lesser influenza infection risk as compared to the erstwhile MERV 7 filters; a change from MERV 13 to HEPA would barely reduce the infection risk by 4% while requiring high investment. This led us to select MERV 13 as the suitable fine air filter for the AHUs. MERV 5 and MERV 8 filters are installed before MERV 13 to reduce the dust loading and to increase the life of the MERV 13 filter. Thus, three layers of filtration are implemented as shown in the table below.

The graph above shows that MERV 13 has nearly 14% lesser influenza infection risk as compared to the erstwhile MERV 7 filters; a change from MERV 13 to HEPA would barely reduce the infection risk by 4% while requiring high investment. This led us to select MERV 13 as the suitable fine air filter for the AHUs. MERV 5 and MERV 8 filters are installed before MERV 13 to reduce the dust loading and to increase the life of the MERV 13 filter. Thus, three layers of filtration are implemented as shown in the table below.

Before retrofitting the AHUs, the total pressure drop is 56mm while post retrofit, the total pressure drop is 89mm. The fan curve of the existing blower is referred to and the maximum pressure handled is reviewed (refer chart given below) which proves that the existing AHU blower can sustain and work satisfactorily in higher pressure conditions without coming under surge condition.

Sterilization of AHU coils with UVGI (Ultra Violet Germicidal Irradiation)

Filtration by itself cannot help to eliminate the fungal / bacterial count hence UVGI technique is implemented along with filtration. The intensity and dosage of UVGI is selected as per the air velocity specified by the ASHRAE 2012 Systems and Equipment Handbook.

UVC Germicidal Ultraviolet wave length (254nm) is effective in penetrating the cell membrane and breaking the DNA structure of a micro-organism. DNA sterilisation inhibits reproduction. Micro-organisms such as mold, bacteria and viruses can be destroyed with the required concentration of germicidal irradiation.

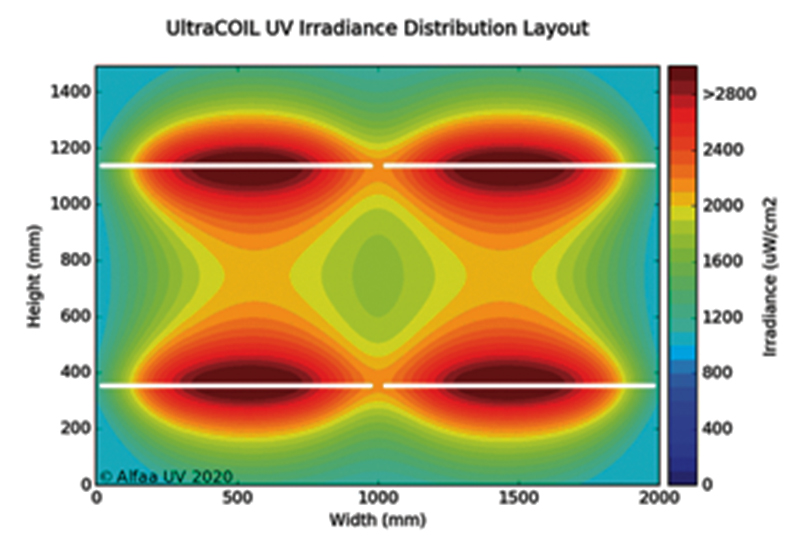

Across our 15000cfm AHU with 2000 x 1490 mm coil, the required intensity and wattage as per the guide is 220 uW/cm2 and 300 W and the chosen UVGI has an intensity of 1915 μW/cm2with net wattage of 300 W.

The CFD profile of UVGI across the AHU coil is shown below. The UV is able to cover the entire surface of the coil as shown here.

Modification of fresh air supply to infuse more fresh air (naturally oxidant – rich) and MERV 5 filter for fresh air damper

Fresh air has a natural disinfectant property with rich natural oxidants, acting as a barrier against COVID 19 virus and other pathogens. Additionally, maintaining humidity between 40 percent to 70 percent and temperature from 240C to 270C is helping to activate virus killing properties in the air. The fresh air dampers are also integrated with MERV 5 filters to purify the incoming fresh air.

Improved Air Recirculation – higher ACPH 8-10, to enhance filtration efficiency

To further restrict the microbial growth, we also reviewed our operational practices and improved the cleaning frequency and methodologies for ducts and AHUs. Double doors have been installed at the AHU room so as to reduce the particle concentration. After the retrofit, 10-12 ACPH is achieved.

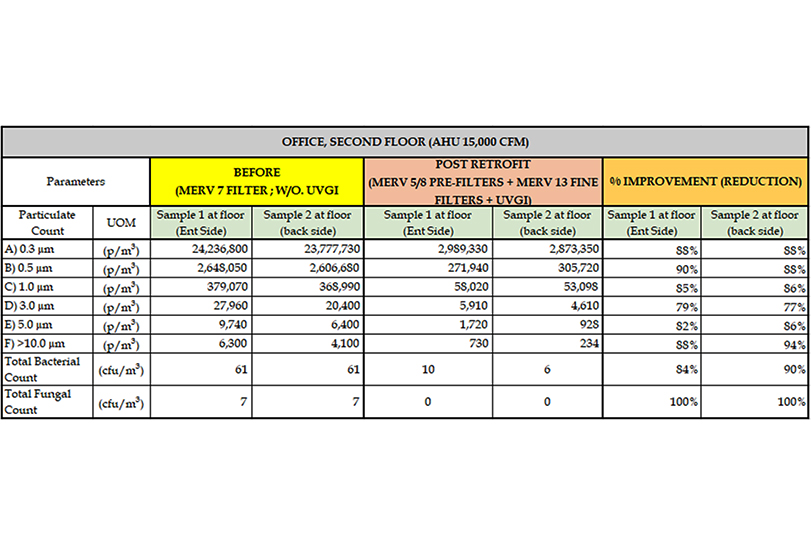

Conclusion: The results of our pilot project have been extremely encouraging ensuring our readiness for the `new normal’. There is a drastic reduction of 84 percent and 90 percent in fine particles and microbes (at rest condition) respectively, which are responsible for transmission/spread of virus through air conditioning.

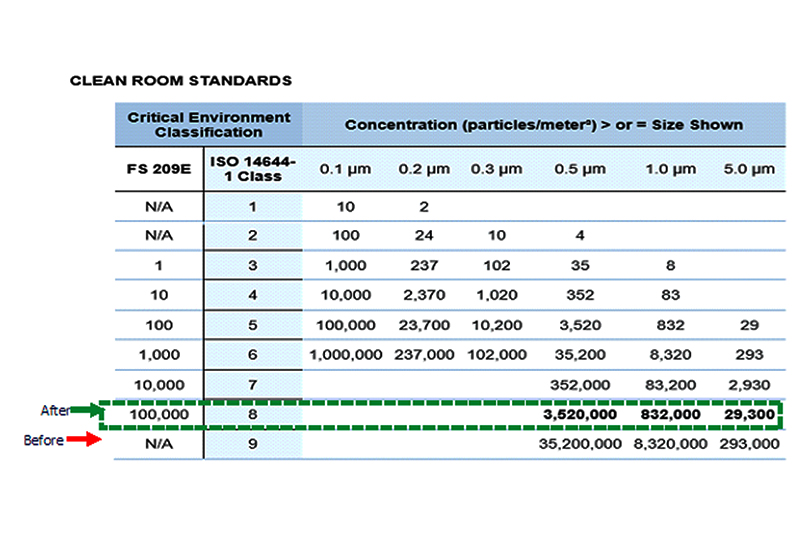

The retrofit results are given below, and with this we have now achieved an ISO 8 class environment.

After reviewing all the results, we are now working towards cloning of technology in other areas. Provision of clean air is thus acting as a big weapon in our fight against the virus.

This article is authored by – Mukesh Suthar, Manager – Internal Services, Godrej & Boyce Manufacturing Co Ltd – Electricals & Electronics

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.