As per reports, the Indian pump market size is valued at USD 2.2. billion in the year 2021 and is expected to reach USD 3.3 billion in 2026 growing at a compound annual growth rate CAGR of 7 percent during the entire period of 2021-2026.

Adding to it, the Indian heating, ventilation, and air conditioning (HVAC) market size is expected to grow to $31,598.6 million by 2030, at a CAGR of 16.0 percent during the forecast period (2021–2030). As per reports, India is among the major players in the data centre sector in the APAC region with the global data centre cooling market projected to reach $27,308.7 million by 2027, growing at a CAGR of 12.8 percent from 2020 to 2027. These Data Centers are further categorised into – Telecom / Edge Facilities – up to 100 KW; IT Server Room -100Kw~500 Kw; Medium and large data center – 500 KW~1MW; Hyperscale data center – 1MW onward.

Although the standard Direct Expansion Precision Ac units are used in Telecom / Edge Facility and Server room to cater the cooling loads which are restricted up to a certain limit, however, as the Data center size increases from category 2 onwards similarly the cooling needs also increase in which a complete HVAC system is implemented. As per ASHRAE reports, the HVAC cooling in a Data center space is close to 30 percent. And, thus a complete HVAC system shall include Chillers, Chilled water type Precision AC units, Fans, Cooling Towers, HVAC Pumps and other ancillary items like Valves and etc. The total power consumption of these systems are as below – (Source: Average building load). Cooling Tower 5 percent, Pumps 25 percent, Fans 30 percent, Chillers 40 percent and Fans 30 percent.

Although Pumps is just taking away a mere 25 percent which is small number as compared to the Chiller but this goes a long way to bring down the operational cost since in most of the building pumps are used as N+1 and N+N configuration and with the present time the prime KRA focus being sustainability of Green Building and Green certifications and similar to reduce the carbon/ water usage.

Selection and implementing the right pumping system is both crucial and critical. The pumping system in HVAC systems basically helps in moving the chilled water from chillers to Air handling units – that is called the Primary Pumps, as a add on to this circuit there is Secondary Pumps as well and further the pumping systems from the cooling tower to the condenser is called the Condenser Pumps if the chillers are of Water Cooled Type Chillers.

The various types and methodology of pumps are- Positive displacement pumps; Piston pumps – Single /double; Rotary pumps – Gear / Screw; Centrifugal / Dynamic pumps; Single / Multi Stage – Horizontal / Vertical.

Types of Pumps in HVAC: Horizontal – End Suction (long coupled and close coupled) and Horizontal Split Case. Vertical – Long coupled and Close coupled. Methodology of Pumps: Primary pumps, Primary – Secondary pumps and Primary – Secondary Tertiary pumps. In types of pumps, the Vertical Pumps are more popular considering energy efficiency and reliability along with the methodology of pumps of Constant Primary-Variable Secondary configuration arrangements in Data center Space or even the Variable Primary pumps are considered to save CAPEX and OPEX.

As a key takeaway point, Chillers Equipment with reduced pressure drop are always recommended to minimise pump head and if the water flow rate can also be reduced, pump energy will be saved. To reduce the water flow and still successfully handle the cooling load, the temperature difference between the supply and return water (the “delta-T”) must increase.The loads must be designed and operated consistent with the higher delta-T. In data centers, good air management means higher return air temperatures to the CRAH units, which means higher chilled water return temperatures, facilitating a higher delta T all methods can help users save the pump cost incurred in the building.

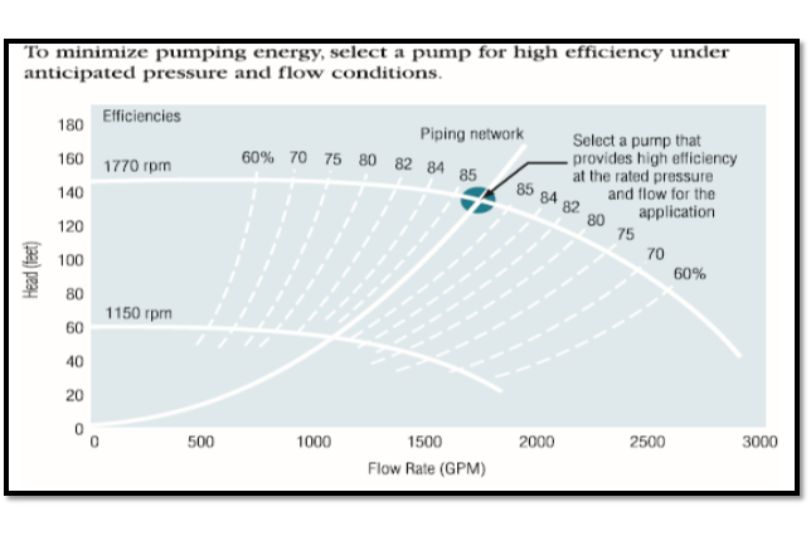

Pump Affinity laws are used in HVAC systems to express the relationship between pump head, flow rate and power. Few of the latest chillers come with variable-flow chilled water operation, which means control valves should be two-way to minimise bypass, and pumps to include variable-speed drives to match flow to load (Source : ECBC 2017 Booklet).User can also refer to ECBC 2017 booklet on the standards and norms to meet the green building while operating the pumps. Valves used in a HVAC system: Plug valves, ball valves, and butterfly valves are the most common types of valves used in heating, ventilation, and air conditioning systems.

Two-way valve is any type of valve with two ports: an inlet and an outlet port and Three-way valves are commonly found in constant flow/ volume pumping systems and can be either mixing or diverting valves. 3-way valves can be piped in the supply or return. The three-way is a compact control valve and actuator system, designed to accurately control water which is used in a Primary – Secondary pumping system. We need to control the pressure difference across the valve to control the flow rate and maintain the temperature differential Delta T ( Supply – Return ) , Hence we see the usage of PIVC Valve which is more popular these days PIVC stands for Pressure Independent Control Valves used either in a Variable Primary or Constant Primary Pumping Systems .

Conclusion

“Let us ensure we design and implement the best energy efficient pumping system and the right set of valves in our HVAC System so that our building consumes low operational cost to meet the Green building norms as we drive towards Sustainable Cleaner and Greener Planet Earth.”

Authored by:

Sandeep Vasant

| CDCP | IGBC-AP | GEM – CP | Member – ISHRAE , CII – IGBC |

Sales Head and Business Development – INDIA ( PAC )

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.