Advancements in air filtration technology and standards like ISO 16890 and Eurovent 4/21 provide effective solutions that maintain energy efficiency while meeting higher air quality requirements. This article explores strategies for enhancing air filtration levels in HVAC systems to meet changing air quality demands without compromising energy consumption.

Clean air is a requirement for all facilities. It helps protect people, products, and processes from airborne contaminants. When enhanced clean air requirements are placed on a building, there is often a concern that this will increase the building’s energy consumption.

Air in a facility

In commercial or industrial settings, HVAC systems should supply clean air to the building. Air filters within these systems ensure the air meets facility-specific standards. Although air quality requirements such as air change rates and filtration levels are often set during building design and construction, these requirements can change.

PM1: People Matter First

Clean air in a building protects the health of its occupants. Implementing air filtration safeguards employee well-being through reduced risks of airborne virus transmission, minimized health impacts from particulate matter, and lower exposure to VOCs and molecular contaminants.

Airflow requirements are typically established based on anticipated work practices during the building design phase. However, changes in these work practices due to various factors may lead to increased air quality requirements. Upgrading air filtration can help meet these new demands.

Clean air standards

When using air filters in commercial or industrial buildings, it is essential to consider efficiency, selection, and energy consumption standards. Understanding these standards is the first step to ensuring increased protection without compromising energy costs.

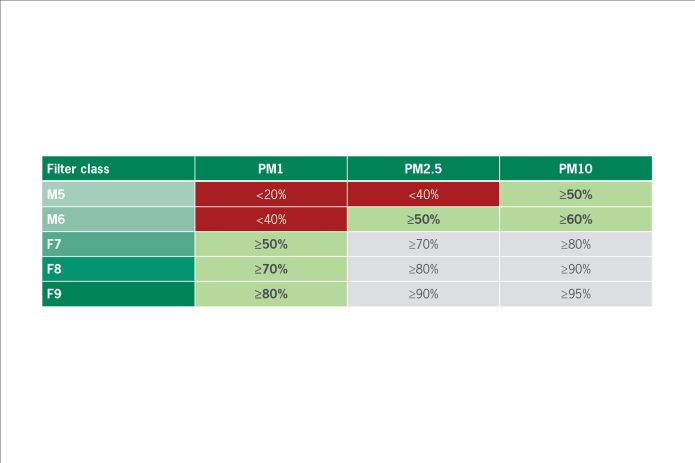

Efficiency standard: ISO 16890

ISO 16890 is the international standard for filtration efficiency. This standard classifies filter selection based on its performance against different particulate ranges. ISO 16890 classifies the performance of your air filter into four main classifications: ePM1, ePM2.5, ePM10, and ePM Coarse filters. The ISO 16890 standard has replaced the EN779:2012 for European filter classification, while ASHRAE 52.2 is still the widely used standard for North America.

Typical efficiencies of air filters against PM1, PM2.5 and PM10 and other fine dust mass concentrations

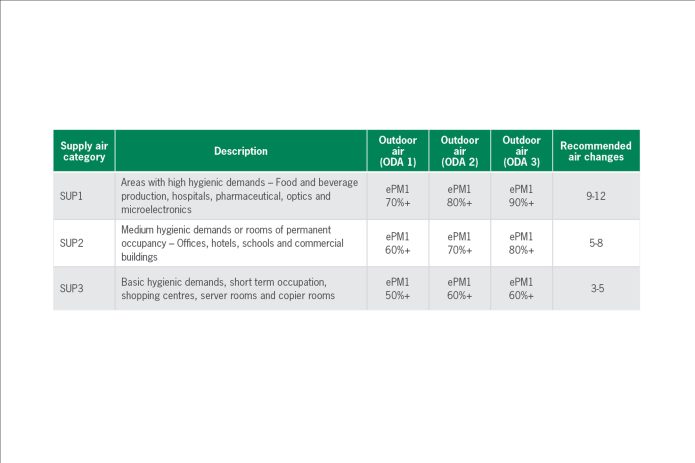

Selection standard: Eurovent 4/23

Eurovent 4/23 was developed in 2017, with further iterations released in 2018 and 2020. The standard guides on the filtration efficiency that should be chosen depending on the building’s commercial and industrial use.

Energy consumption and filter

The air filter does not consume energy; the fan within the HVAC system does. The filter causes a pressure drop in the HVAC system. The higher the pressure drop, the harder it is for the fan to maintain the air volume.

Filters can contribute up to 30 percent of total energy consumption in an HVAC system, but they are an easily exchangeable maintenance part. So, choosing a low-energy, long-lasting filter can influence the

total cost of ownership.

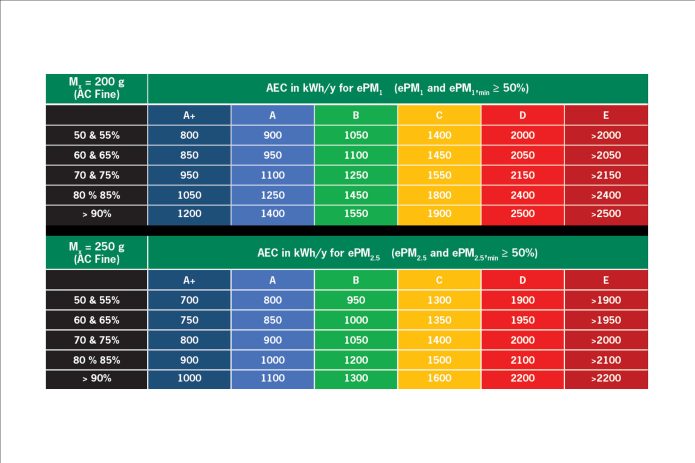

Energy consumption standard: Eurovent 4/21

Since the air filter can account for such a large proportion of the HVAC system’s total energy costs, a new energy rating was developed in 2014, with the newest update encompassing the ISO 16890 classifications.

In this system, air filters are grouped based on their efficiency levels, with an energy rating ranging from A+ to E, reflecting each filter’s direct impact on energy consumption.

Energy rating

Every filter tested and certified against the Eurovent 4/21 standard must display the energy rating on the box. The label shows the standard design of all Eurovent-tested air filters.

The label displays the standard design for all Eurovent-tested air filters, providing filtration efficiency, annual energy consumption, and filter rating information. It allows for quick and easy comparison between different filter options.

Supply air upgrades

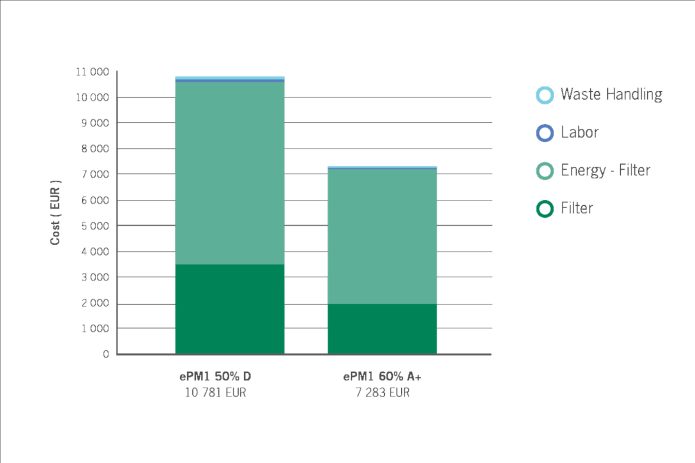

A building owner wants to upgrade its filtration efficiency to help reduce the risk of airborne virus transmission. The customer has one AHU that houses ten filters in the system. The study was based on a 3-year lifecycle to evaluate the system.

To help protect buildings from the spread of airborne viruses, REVHA https://www.rehva.eu/about-us/who-we-are/about-rehva recommends supplying air filtered using an ePM1 60 percent filter at a minimum.

By Upgrading efficiency but choosing an A+ energy-rated air filter, the system operates with €2000 less in energy consumption over the three years. This upgrade enhances employee protection and reduces costs. Additional benefits include fewer filter replacements, which reduce labour expenses, less waste, and a decrease in overall filter costs throughout a project’s lifetime.

Recirculation air upgrades – Upgrading efficiencies

Air recirculation in buildings was introduced as an energy-saving measure. The need for additional cooling and heating was reduced by reusing indoor air, allowing companies to save on energy costs. The problem with this method is that indoor environments are up to 50 times more polluted than outdoor air which means an increase in filtration levels is required. During airborne virus outbreaks, the recirculation system can spread the infected air around the building. This means higher levels of filtration will be required.

Recommendations

Given the vast volume of outdoor air, the risk of airborne viruses entering the supply air system is low. However, recirculated air, which reuses indoor air, can contain higher concentrations of viruses. Therefore, in commercial and industrial buildings, it is recommended to turn off air recirculation when there is a risk of virus transmission. If recirculation air is required for energy savings initiatives, it is recommended that an ePM1 80-85 percent filter is used in this environment.

Employing ePM1 80 percent+ filters in a recirculation air system allows previous energy-saving initiatives to continue. Camfil’s LCC software can recommend the most energy-efficient filter upgrades, improving the total cost of ownership of filtration systems.

For more info, visit www.camfil.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.