Technology is revolutionising the way a HVAC system operates and how we interact with the systems. Here’s a report on how IT is reshaping the HVAC industry.

The rapid growth of industrial automation and information technology (IT) is enabling all industries today to ease the process of manufacturing and redefine the profitability of these industries through effective utilisation of energy and manufacturing components. According to Anuraaga Chandra, Head – Cooling Sales, Danfoss India, “With the advent of digitalisation, the manufacturing industry has also been able to build capabilities in newer business models adding significant value to the industry, both from an energy-efficiency and safety perspective which in turn creates opportunity for ‘smart manufacturing’. This ensures that there is less wastage of resources, increased productivity, better quality, faster time-to-market, integrated supply chain and better security.”

Commenting on how IT is reshaping the HVAC industry, Varun Pahwa, President, DRI – Pahwa Group, said, “IT, just as, HVAC is everywhere. Sensors and controls powered by IT manage smart buildings. BMS (Building Management Systems) are all IT-based. Even equipment and systems are controlled by IoT (Internet of Things).”

Neeraj Gupta, Senior General Manager – Living Environment Division, Mitsubishi Electric India Pvt. Ltd. opines: “IT is majorly contributing to the HVAC industry through efficient control, monitoring, and reporting segments. The usage of HVAC systems is increasing in commercial and industrial spaces.”

Today, the HVAC systems are being integrated with various home systems and giving a mileage to process called building automation. Now with the help of IT products and services; the HVAC system can troubleshoot, operate and monitor through laptop or desktop as well as cell phone or tablets. Similarly, due to IT, we are getting uses reports, tenant power billing reports, breakdown reporting, etc. In recent years, cloud computing has enabled us to connect our HVAC equipment with the home automation system.

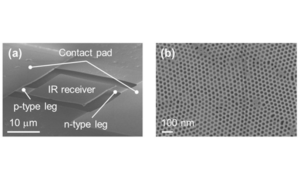

Gaurav Mathur, Associate Vice President – Sales Development (Building Services) Grundfos India explains: “As we see the rapid wave of digital transformation setting in almost every industry, the HVAC industry has joined the journey by incorporating digital solutions to produce efficient and sustainable products. Industry 4.0 technologies are being introduced to traditional HVAC solutions to augment its existing utility. Intelligent pump solutions with smart sensors can be used to collect data such as indoor and outdoor temperature to provide actionable insights.”

Intelligence of Things (IoT) is the complete platform of value-added services that can allow a new experience in interacting with units, from users in the field to managers in the office, all via Cloud services, observes Daniel Chen, CAREL – APAC Marketing Manager (HVAC).

For example, the CAREL IoT platform – new data processing technologies combined with CAREL’s thermodynamic expertise – can be integrated into cloud portals to provide users with useful information to make everyday activities easier and more effective. The useful data are in fact collected and presented on dashboards for energy managers, service teams and quality departments. Specific views are customised for marketing managers and property managers, for different applications. Data from the field are processed using the latest machine learning technologies, applying predictive models for the development of new predictive maintenance services and performance optimisation.

“IoT platforms can save hours on alarm management by focusing on any current critical conditions, thanks to alarm priorities and filters. Journeys on site can be reduced thanks to in-depth, remote technical analysis,” Daniel said.

Moreover, he adds, “Energy saving can be achieved by focusing the experts’ work on the most critical sites only, using a normalised league table, driving the priority of analysis with targeted consumption clustering.”

The IoT platform can also manage standard reports automatically and increase global quality by focusing only on critical equipment. This means reducing waste of goods and customer claims and increasing user satisfaction.

Grundfos has designed a range of products that caters to the ongoing demand of the HVACR industry. Grundfos brings in some interesting and intelligent solutions like, iSOLUTIONS, which is an intelligent solution that encapsulates innovative solutions to the products across spectrums. These solutions use sensors to understand the flow and pressure of water. iSOLUTIONS enable real-time monitoring, remote control, fault prediction and system optimisation to help you reach a new level of performance. This improves adaptability while simultaneously improving predictive maintenance and enabling remote monitoring thereby bringing about energy efficiency and water conservation.

In comparison to a fixed speed pump, Grundfos Magna3 circulator provides about 75 percent more energy savings, claims Mathur. He said, “These high-performance pumps are perfect for high-performance building systems and fit both heating and cooling applications. Grundfos TPE3, an in-line vertical pump with an in-built controller, delta-pressure and temperature sensor, is an all in one package that can be used in heating, cooling and district energy systems. These pumps come with a variable frequency drive that has the best in class IE5 energy efficiency optimisation. All these efficient technological developments have the potential to be cost-efficient as well as energy-efficient in the longer run.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.