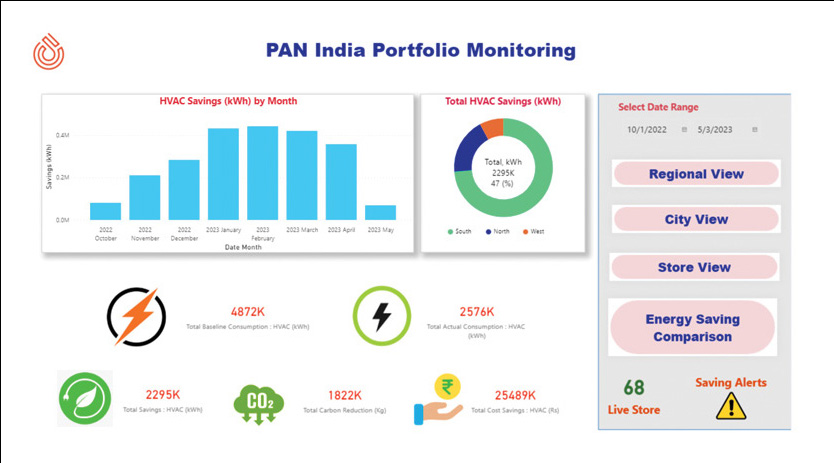

Karn Chaturvedi, General Manager-Technical at 75F APAC, highlights the potential of IoT technology in enabling the placement of wireless meters and sensors for seamless data collection. These sensors communicate wirelessly and gather data that can be conveniently presented on a user-friendly dashboard.

With increasing awareness of Energy Efficiency, adopting efficient cooling equipment has seen an uptick. According to a US Environmental Protection Agency study, 30 percent of the energy consumed in buildings is wasted due to poor HVAC Controls and lack of visibility on the energy leaked. Closer to home, as per India Cooling Action Plan (ICAP), by 2030, the energy required to cool our commercial buildings and cities will more than triple to 20 percent of energy use and carbon emissions nationwide. As plans for new construction rapidly accelerate and cooling energy needs rise, the India Economic Survey warns that equipping our commercial buildings with clean, healthy technology is essential to the quality of life and our planet. It is important to upgrade the controls of these existing buildings to improve the energy performance of the building’s stock in general.

With the advent of IoT, Cloud and Edge Computing technology, it is now possible to deploy HVAC Controls which can incorporate the latest energy-saving algorithm, which can be deployed quickly with minimum disruptions, which allows the end users greater visibility and actionable insights on the energy efficiency of the buildings.

Mastering part loads with an energy-efficient algorithm

The building’s response to part load is very important, as the cooling demand at floor level or building level stays in the part-load range more often than the design installed capacity. However, cooling loads within most buildings are dynamic and change between various zones during the day. This requires the controls to quickly respond to the changes in cooling loads to ensure efficient cooling, especially during the part load condition. The legacy air distribution control method was to individually control the comfort in the zones using devices such as VAV, Thermafusers etc.. The system will respond based on aggregating variables, such as Duct Static Pressure or Return Air Temperature. These values do not consider the distribution of loads throughout the zones and are also quite slow to change the system response.

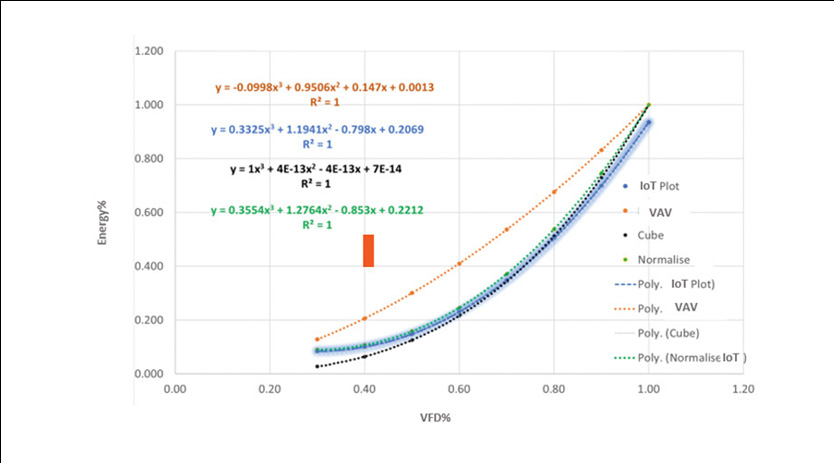

However, IoT technology allows various zones and subsystems to communicate directly with the central plant with minimal wiring and often utilising wireless technology. Combined with new Energy Efficient control sequences, this allows different zones and subsystems to directly communicate with the Central Plant Controller and fine-tune control response based on the current loads seen by individual zones as subsystems. This improves the central plant response to provide cooling in the part load condition. An example of this is shown in Figure 1, where IoT Air Distribution performance is matched against VAV performance for the same AHUs. The former can save more energy for each frequency of the AHU VFD compared to the VAV control sequences.

This trend is wider than just the air side, where ASHRAE has recommended a similar control sequence for the operation of Chiller Plants as per the ASHRAE GPC 36: 2021.

Ease of retrofit installation

Building Controls retrofits are good carbon-effective options to provide energy efficiency. Instead of changing the high-side HVAC equipment on site, which requires significant capital costs and disruption of operations, a more ROI-friendly option is to upgrade the controls. This option further prevents the accumulation of embodied carbon emissions by bringing in large HVAC equipment. It can be used to further extend the life and performance of existing HVAC equipment without compromising on energy savings and comfort. IoT Technology helps provide easy-to-deploy wireless sensors and controllers capable of analysing the existing system’s performance and judging the suitability of a control retrofit with minimum disruption of site operation due to the need for running cables. Further, storing the data on the cloud analyses data and provides an avenue for automated analysis with minimal human intervention.

HVAC Controls are often programmed from the ground up per each site’s requirement. However, most deployments have typical control sequences and require the deployment of the same control with small site-based adjustments. Many IoT Controllers come with in-built control sequences, making deploying the control sequences quicker and more reliable. Having built-in control sequences also reduces the reliance on operators to make on-site adjustments which can be sources of error during the operation stage. This ensures that the energy efficiency of a well-commissioned site can be maintained for a longer period.

Providing visibility of energy usage

The adage “whatever gets measured, get managed”, also rings very true in the space of HVAC Controls. The clients want to see the impact of their capital expenditure on the control systems and see the return on their investment, which might be better energy savings, better comfort, better IAQ or all of the above. Often, the data is stored in the Building Management System servers and is not readily available for the higher management to view. Additional time and workforce are required to analyse trend data to show the outcome to the decision-makers.

Using IoT technology, it is possible to place meters and sensors which communicate wireless and collect the data in a ready-to-present dashboard. These dashboards can be customised to meet the client’s requirements and can be updated in real-time. For illustration, refer to the dashboard attached showing the energy savings achieved in multiple stores in Figure 2.

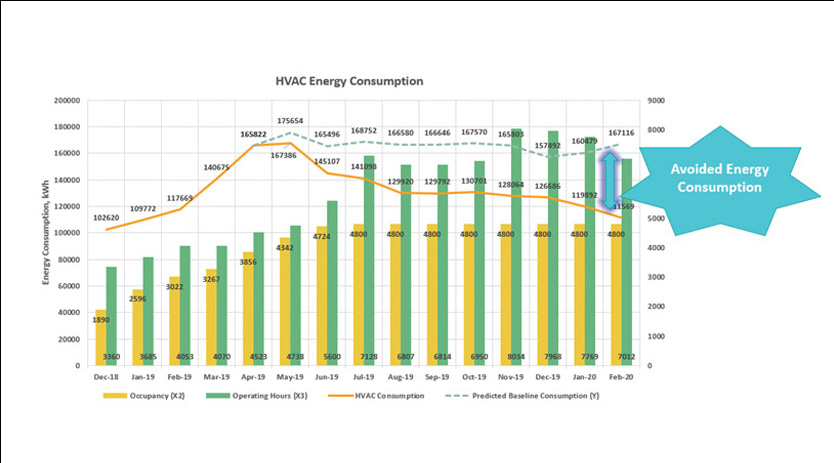

IoT cloud technology even allows geographically disparate sites to connect to one system and provide for multiple sites in one view. It is also possible to conduct advanced regression analysis to account for energy changes due to external factors such as increased occupancy, longer working hours, or differences in climate etc., as shown in Figure 3.

In conclusion, while it may not provide a new cooling mechanism that radically improves energy efficiency, it is still possible to reduce the carbon emissions of existing and new buildings using IoT technologies.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.