The company’s ThermaClear HVAC treatment dramatically reduces buildings’ carbon footprints, saving thousands of dollars in operating expenses and electricity costs.

The product ThermaClear™ extends the life and efficiency of HVAC systems with just one treatment, resulting in radical carbon footprint reduction and energy savings of up to 15 percent annually. Phoenixbased ECM Technologies has been awarded a $2.1 million City of Phoenix contract for up to 12 million square feet of conditioned space after running numerous successful and long-term pilot programs over the past four years in the Valley. ThermaClear radically extends the life and efficiency of HVAC systems, resulting in carbon footprint reduction and substantial energy savings, up to 15 percent annually.

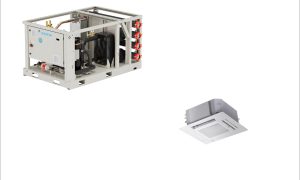

The company has treated over 12,000 tons of HVAC equipment, servicing more than four million square feet of building-conditioned space. All makes and models of significant HVAC equipment types have been successfully treated, ranging from one-ton mini-splits to 2,000-ton, watercooled chillers.

ECM Technologies Managing Director David Fenton said, “The City of Phoenix’s confidence in ThermaClear and our ability to substantially impact the City’s carbon footprint and save it up to 15 percent in annual energy costs speaks volumes as we move to officially launch ThermaClear here in the Valley. We look forward to implementing our treatment at various City facilities and assisting in its laudable efforts to go carbon neutral by 2050.”

The proprietary nano-fluid works by clearing away the oil coating that migrates into the HVAC system’s heat exchanger coils and creating a barrier against future buildup. Results include Reduced energy consumption, energy costs, carbon emissions and improved HVAC efficiency. The typical ThermaClear payback period ranges from 24 to 36 months, resulting in HVAC electricity consumption savings of 10 to 15 percent annually.

Only one treatment is needed for the life of the HVAC system, and is backed by a full warranty for the remaining useful life of the equipment.

City of Phoenix Public Works Energy Management Specialist Jim Gorombei said, “In 2016, the City of Phoenix established its 2050 goal of becoming a carbon-neutral city, and the use of innovative technology such as this will play a role in that effort. The City performed several pilot demonstrations with ECM Technologies and was satisfied with the results, therefore contracted with the company to implement its ThermaClear treatment in various facilities.”

Phoenix Art Museum

ECM Technologies’ pilot programs used single ThermaClear treatments on various buildings, including Phoenix Art Museum, Phoenix Sky Harbor Airport, Arizona State University etc. Savings results were demonstrated at every pilot property location and validated by third-party, independent professional engineers and analysts. The museum must maintain stringent temperature and humidity conditions and backup air conditioning systems to cool and protect the highly valued art with ThermaClear.

Overview

The Phoenix Art Museum has a rich history of displaying some of the world’s most prolific art for over 60 years. At any time, it houses nearly 20,000 pieces of art enjoyed by over 300,000 visitors annually. The museum must maintain stringent temperature and humidity conditions and backup air conditioning systems to protect the highly valued art. The City of Phoenix maintains the art museum facility. As a result, the building’s energy consumption and carbon emissions impact the City’s operating costs, as well as its goal to become carbon-neutral by the year 2050.

Phoenix Leadership engaged with ECM Technologies to work with the City’s energy-planning and facilities and sustainability teams to treat the art museum’s HVAC systems with ThermaClear™.

- Savings

- Estimated annual energy reduction

- 106,756 kWh

- CO2 equivalent savings

- 75.7 metric tons

- Estimated annual carbon reduction

- 8,513 gallons of gasoline.

“I was extremely pleased with the ease of the treatment process. Applying this Energy Conservation The measure was quick with virtually no involvement of the client nor required any downtime of the equipment.”- Chiller Equipment Service Technician.

Creating efficiency gains averaging 10 percent on a Trane 350-Ton water-cooled chiller to prove the efficacy of ThermaClear™.

Unit Type: 350-Ton Water-cooled chiller

Conditioned Space 285,000 ft2 .

Critical cooling needs

- Tightly controlled temperature and humidity are required to preserve fine artwork.

- Verified controls with built-in backups, including additional backup chillers.

- Year-round cooling is required.

Performance Measurement & Verification

ThermaClear™ performance was validated through comprehensive, real-time monitoring throughout ECM Technologies’ research and development process.

Our monitoring system adhered to International Performance Measurement and Verification Protocol standards to capture key indoor and outdoor metrics like temperature, humidity, chilled water / airflow and energy consumption.

Data were recorded every minute over an extended testing period, ranging between 3 and 9 months per test, to capture both pre- and post-treatment data.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.