Use heater control panels with thyristor power regulators to achieve precise temperature control for your oven, furnace, or air handling unit.

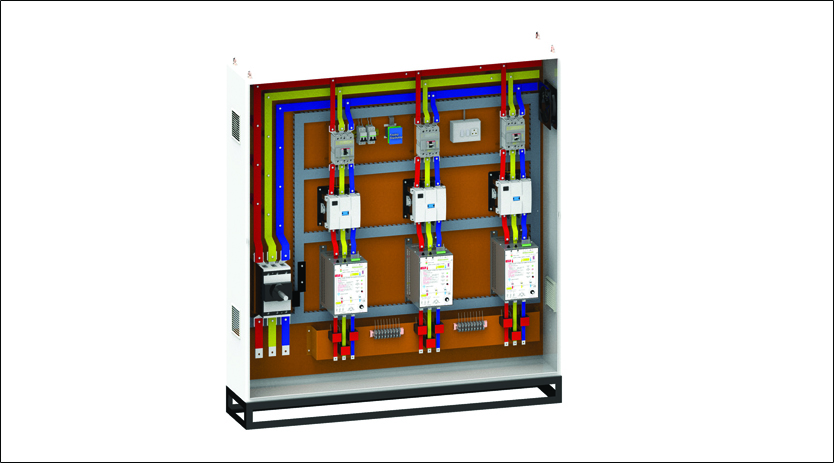

Libratherm electrical control panel systems use PID controllers and thyristor/SCR power controllers to regulate the power supplied to the heating elements. Temperature sensors provide data to the PID controllers, which signal the thyristor power regulator to adjust the power output accordingly. With continuous temperature monitoring in a closed-loop control system, Libratherm control panels include all the necessary components, such as safety switch gears, busbars and power cabling, thermal regulation, and an enclosure. This comprehensive solution offers customers a ready-to-use system for controlling their heating equipment.

Benefits of power control systems using Thyristors

The Thyristor Power Controller is a reliable and precise tool for managing the process in proportion to the control signal. It offers a seamless approach to regulating the power supplied to the load. Unlike Contactors, Thyristors do not have any mechanical movement, eliminating the risk of sparking, arcing, and carbon buildup. They gradually supply power to the heating load, preventing electrical surges and transients and ultimately extending the lifespan of the heating components. Using Thyristor power controllers can enhance the energy efficiency of heaters by reducing energy losses as they can be turned on and off quickly, which reduces the time the heater consumes power. They are ideal for industrial applications where dust, dirt, or moisture may pose a risk. Libratherm has a range of Thyristor Power Controllers that can handle loads from 10A to 1000A. The Libratherm Thyristor power controllers come equipped with a current limit and overload trip function that safeguards the valuable heating elements against damage caused by overload. This feature also eliminates the requirement for physical fuses that the user must manually replace in case of an overload trip.

Applications

Thyristor power controllers find their use in various applications where there is a need for accurate and precise control of heaters. These applications include:

• Aluminium Melting Furnaces

• Holding Furnaces

• Air Handling Units

• Dehumidifiers

• Boilers

• Hot Air Generators and Hot Air Dryers

• Very high-temperature furnaces built using Silicon Carbide/MoSi2 heating elements

• Microwave dryers

• Multi-zone Drying and Curing Ovens

• Heat Transfer Printing Machines

• Food Grains, Paper and Printing Drying Ovens made using Quartz tube Medium

• Wave IR and Ceramic coated IR heaters.

• Pet bottles Pre Forms preheating tunnel ovens made using IR heaters

• Plastic Injection moulding requiring multi-zone heating for manifold moulds

• Plastic Pipes and Sheets extrusion

• Metal sheets welding system.

For more information, visit www. libratherm.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.