Space heating and cooling are necessary requirements in the technically advanced world, and they are of great concern to HVAC industry engineers. To address reliability and performance issues in buildings and offices of all air handling HVAC systems, a detailed analysis of operational data from laboratory units can help understand the main variables that affect the performance and functioning of all-air distribution systems. This article presents some results from operation data analysis of a VCRS-operated AHU serving a test enclosure reasonably insulated from the surroundings.

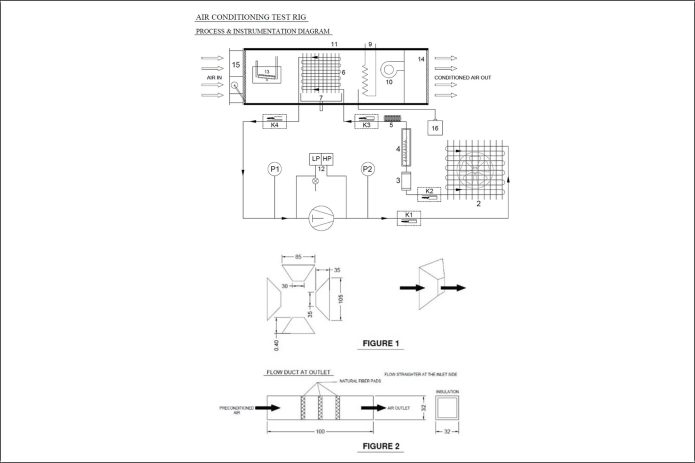

The relative humidity in the Panjim location ranges from 60 to 90 percent throughout the year. An experimental setup from the conventional Air conditioning test rig housed in the laboratory is derived. The laboratory setup is located in the coastal area of Panjim, and the humidity and purity of air are Major concerns. It has a 1 TR rated capacity of cooling employing a vapour compression cycle system (VCRS) having an Air Handling unit (AHU) comprising of an inclined tube manometer, an evaporative coil with the drain pan, an air heater, an evaporator cooling fan, and an insulated air duct. The setup is used for experiments like capacity calculation, air handling unit heat transfer characteristics, and plotting thermal comfort zones on a psychrometric chart.

The experimental setup is modified by providing a convergent flow straightener at the inlet, an insulated air duct at the outlet, and an extension duct running through the enclosed test cabin space.

In the last decade, with the greater demand for human comfort, Vapour compression air conditioners have dominated the cooling sector due to their high efficiency, practicality, and technological maturity. The energy-efficient direct Evaporative cooler decreases the temperature of the ambient air before it passes over the condenser coil, thereby decreasing the pressure and temperature of the condenser, so the mass flow rate of the liquid refrigerant and its cooling capacity also increases. Also, using local natural fibres, air handling unit performance will be experimentally investigated and analysed for enhanced indoor air quality and human comfort. A novel approach of Radiant Cooling Technology is employed to improve the performance of the AHU by incorporating it in the C-shaped microclimatic Zone with staggered copper tubes specially fabricated to achieve indoor air quality and comfort conditions in the test chamber.

In urban Goa, staying indoors is uncomfortable without a perfect cooling system. An air conditioner is a Major home appliance globally that changes the temperature and humidity level inside the room. But, if not taken care of, it can cause serious health issues in people of all age groups. Studies have shown that dry air or very humid air affects the human body in the following ways:

- Breathing improper air is a potential health hazard.

- Skin moisture evaporation can cause skin irritations and eye itching.

- Due to improper air for many years, the synovial fluid of the joints, which acts as a lubricant, begins to dry up due to evaporation.

- Arthritis joint pain inflammation is increased more because cold and dry air from the air conditioner is blown off.

- Uncomfortable sinus and respiratory problems

These problems can be reduced by maintaining indoor relative humidity. The direct evaporative cooler can increase this, but due to the prevailing high-humidity air in Goa, the direct evaporative cooler alone cannot reduce the Room temperature to human comfort conditions. Hence, it is necessary to use a direct evaporative cooler in conjunction with a conventional vapour compression air conditioning system that brings the air temperature to human comfort conditions.

The novel approach with a C-shaped chamber of radiant cooling pipes will further enhance the cooling effect by decreasing humidity and improving indoor air quality and human comfort, which will be validated through real-world human surveys.

A Single duct setup for testing the effectiveness of the natural fibres and cooling pads is proposed for fabrication. The schematic of the proposed Experimental setup will be as follows:

Experimental Air Conditioning tutor with AHU

Modified Experimental Setup with insulated Duct & inlet flow straightener (Fiber cooling pads before condenser & Evaporator)

Evaporative Cooler in Conjunction with VCRS

Natural Fibre Cooling pads

The CFD Model

The radiant cubicle system and the surrounding room are modelled using ANSYS Workbench, i.e. ANSYS DESIGN MODELER, keeping all the geometrical parameters the same as in the existing experimental setup.

Model of the cubicle in the room integrated with the HVAC System

Radiant Cooling Microclimatic Zone has been created in the laboratory at Govt Polytechnic Panaji.

The fabrication setup, along with equipment calibration, natural fibres, and additives, is available at Government Polytechnic Altinho, Panaji, Goa. Modifications to the AHU’s inlet and outlet have been completed.

To reduce energy consumption and improve the system’s performance, novel methods like using evaporative cooling to cool air over the condenser, local natural fibre cooling pads before the condenser and evaporator, and also in the outlet duct will be tried, and performance will be analysed.

Local natural fibre cooling pads made up of local coconut coir, cotton, Jute, Sugarcane, and khus fibre pads will be tried and tested by adding additives like CMC H7 and other additives for various air velocities and temperatures of outdoor air. The experiment will be performed for all four seasons: Spring, summer, fall, and winter, and the effective cooling effect for comfort conditions will be deduced.

Experimentation

Actual Readings were taken in different seasons to assess indoor air quality and thermal comfort using a conventional 1 TR HVAC system. After a detailed analysis, the summer season readings for April are considered to be in the middle of the day (afternoon).

Boundary conditions used

Indoor Parameters: Dry Bulb Temperature – 33 0c and relative Humidity 65%

Internal walls and floors: heat flux density is 17 W/m2

• Window is made up of glass

• Air Inlet Velocity: 3.2 m/s2 and supply air Temperature is kept constant at 25°c.

• Water inlet Temperature for copper tubes: 26°C and the Dew point Temperature is 24.6 °C

For simplicity of the model, the temperature of the radiant pipe was kept constant for a case throughout the simulation CFD Results of Temperature Contours

Assumptions for CFD modelling

The study used ANSYS FLUENT 2023, which used the finite volume method to convert the governing equations into numerically solvable algebraic equations.

- Turbulence Model: k-ω Model

- Radiation Model: Surface Surface Radiation in FLUENT accounts for Stefan Boltzmann’s laws of surface radiation

- The numerical investigations were based on the following assumptions:

- Thermo-physical properties of aluminium, concrete, human, and air remain constant during operation.

- Thermal contact between the chilled water pipe and its surroundings is perfect.

- Initially, room air temperature, chilled water pipe and panel temperature are considered equal and undisturbed.

Conclusion

Using an Evaporative Cooler in conjunction with VCRs and natural fibre pads in the single ducting and a radiant C-shaped microclimatic chamber can produce effective and low-cost enhancements in cooling efficiencies, as seen in the work mentioned herein.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.