Prashant Sinha, Head of Marketing, WIKA India, explains as the HVACR industry adapts to meet the demands of sustainability and efficiency, WIKA stands at the forefront with sensor-driven solutions that enhance safety, cost-effectiveness, and environmental responsibility.

Please discuss WIKA’s test and measurement tools for enhancing safety and efficiency.

Heat exchangers play a pivotal role in facilitating safe and sustainable heat transfer. This ensures optimal process and energy utilisation in various industries. They serve essential functions in different applications. Moreover, in the HVACR field, heat exchangers play a vital role in regulating indoor temperatures by exchanging heat between air streams. In the chemical sector, they help to maintain the proper temperatures during reactions. In power generation, they boost thermal efficiency by recovering waste heat from exhaust gases. In automotive settings, they assist in engine cooling and enhance fuel efficiency. All these devices greatly contribute to industrial processes and energy conservation. This optimises output and safety.

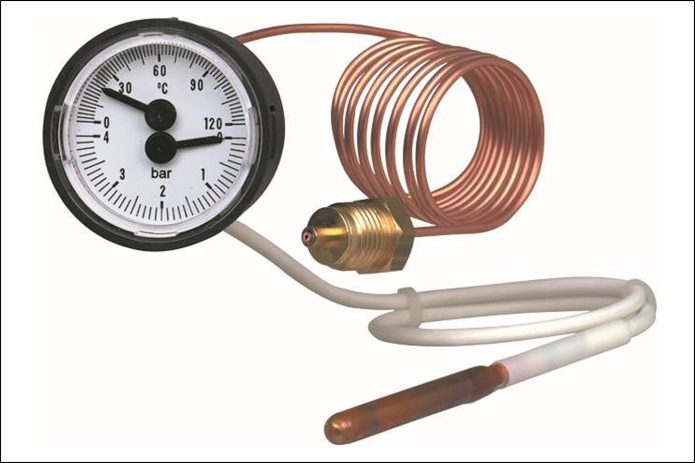

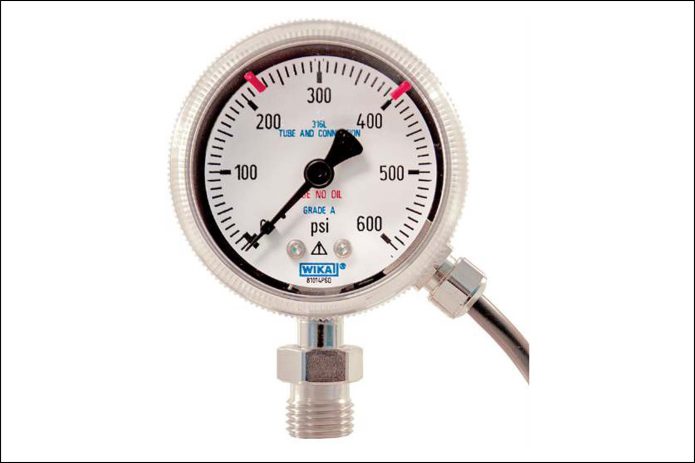

Heat exchangers’ performance is checked and enhanced using monitoring equipment. It monitors temperature, pressure, and fluid flow, ensuring efficiency and safety. These tools can identify leaks in heat exchangers and assess the integrity of materials used in heat exchangers. The tools help with preventive maintenance for dependable performance. It ensures the reliability of heat exchangers. WIKA India offers customised solutions for heat exchangers to meet the specific needs of various industries.

What advancement in technology is reshaping the future dynamics of the HVACR sector?

Amidst the technological revolution reshaping various industries, the HVACR sector has embraced state-of-the-art advancements. These innovations aim to enhance sustainability and energy-efficient operations in HVACR systems. Numerous emerging technologies are steering the HVACR segment towards enhanced functionality. Here are some innovations reshaping the HVACR sector’s future dynamics.

Smart HVACR systems: By leveraging wireless connectivity, individuals can now use their mobile devices to manage their residential HVACR systems remotely. It enables them to set triggers and controls according to their preferences and needs. Smart air conditioners, controllers and programmable thermostats automatically synchronise with external temperatures, ensuring customer preferences while considering environmental impacts.

Geothermal heating and cooling: This eco-friendly option significantly reduces carbon footprints by utilising heat pumps, water and an underground piping system to cool homes naturally. These systems eliminate the need for refrigerants and instead exchange heat with the ground.

Thermally driven air conditioning: This HVACR technology is being experimented with to provide an energy-efficient cooling method that uses solar energy instead of electricity. When solar energy is not available, natural gas is an alternative power source to reduce electricity costs.

How does this technology enable predictive maintenance, reducing the overall costs associated with the repair, maintenance, and installation of these systems?

The advent of digital technology has wholly transformed HVACR systems. It allows users to set and manage room temperatures through their mobile devices remotely. This can customise the system to their needs. Smart HVACR units utilise intelligent vents, thermostats and sensors to optimise cooling, thus minimising energy consumption. These sensors detect changes in external temperature and gauge the ideal room temperature based on occupants’ preferences. They track room movement and activity levels to modulate cooling accordingly. IIoT and AI are vital in ensuring predictive maintenance in HVACR technology. These intelligent machines promptly alert customers about the need for timely servicing, thereby decreasing the repair, maintenance and installation cost of these systems.

Could you elaborate on how customised sensors, such as those provided by WIKA, enhance safety and efficiency across various industries?

WIKA provides various smart instrumentation products with customised sensors to cater to various industries. Their product range includes differential pressure gauges with pressure switches for monitoring tasks like air filter performance, industrial cooling system operation, and ventilation duct flow control.

The sensor-driven technology controls air and fire shutters effectively. These products can predict and regulate the heating and cooling requirements per the environmental conditions. Smart vents with alarm sensors can identify gas or carbon monoxide leaks and trigger safety systems. Fire protection sensors detect unnecessary spikes in heat in industrial manufacturing spaces. The thermographic testing and inspection measure surface temperature using infrared video and still cameras. It ensures the unhindered functioning of machines without downtime.

Furthermore, the system’s software sends a timely alert to the maintenance department in case of any malfunction, aiding in predictive maintenance. It ensures the sustainable operation of the devices.

What instrumentation range is available to maintain quality indoor air in buildings?

WIKA provides an extensive array of instrumentation designed for the HVACR industry. It encompasses heating systems, solar thermal systems, heat pumps and related technologies. Within each category, the company offers a diverse selection of measurement equipment. The equipment includes a comprehensive range of high-quality dial thermometers for precise temperature measurement in industrial HVACR applications. These sensor-enabled devices always ensure optimal air, temperature and pressure in the building.

Can you share how WIKA is leveraging IoT and digitization to enhance the capabilities of its HVACR products?

The advent of digitisation has opened up significant opportunities for HVACR systems. The market has moved towards smart HVACR, which enables remote monitoring and control of the systems via mobile devices. Integrating various IoT sensors has made HVACR devices more refined and prepared for the future. Remote monitoring has become a crucial aspect across all industries. It allows users to oversee a range of parameters, such as temperature, pressure, airflow, humidity, and air quality, through their mobile devices. This enables us to take immediate action in case of any anomaly. Even in residential settings, users have complete control over these smart devices and can remotely adjust various parameters as needed.

Can you share some innovations demonstrating the company’s commitment to sustainability in HVACR?

The global HVACR technology is shifting its focus towards sustainability, cost-effectiveness, efficiency and comfort by implementing smart and eco-friendly automation. WIKA continuously supports this evolution by manufacturing diverse sensor-enabled devices, such as temperature switches, pressure switches and bimetal thermometers. These innovative products improve the functionalities of HVACR devices, enabling HVAC in an eco-friendly, safe and cost-effective manner.

The company is also focused on developing future-ready smart instrumentation solutions. The future trends of smart homes and smart manufacturing will further accentuate the need for fully automated, super-efficient, self-learning and sustainable HVACR systems. WIKA, with its array of IoT-enabled T&M solutions, is well-positioned to meet the demands of the constantly changing market trends.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.