Camfil provides clean air solutions for facilities and the environment to protect people, products, and processes from airborne contaminants. Despite the importance of clean air, building owners may hesitate to upgrade their air filtration systems due to concerns about increased energy consumption.

To ensure clean air in commercial and industrial environments, HVAC systems play a crucial role. The air filters in these systems are responsible for maintaining the desired air quality within the facility by screening out contaminants.

One of the primary functions of clean air is to safeguard people’s health inside buildings. Proper air filtration can help reduce the transmission of airborne viruses and mitigate the negative health effects caused by particulate matter, VOCs, and molecular contamination.

Airflow requirements in buildings are typically determined based on anticipated work practices during the design phase. However, changes in work practices can result in increased air quality needs. Upgrading air filtration systems can help meet these new demands and ensure the continued delivery of clean air.

Clean air standards

Efficiency, selection, and energy consumption standards are crucial when using air filters in commercial or industrial buildings. Familiarising oneself with these standards is the initial step in achieving greater protection without sacrificing energy efficiency.

Efficiency standard: ISO 16890

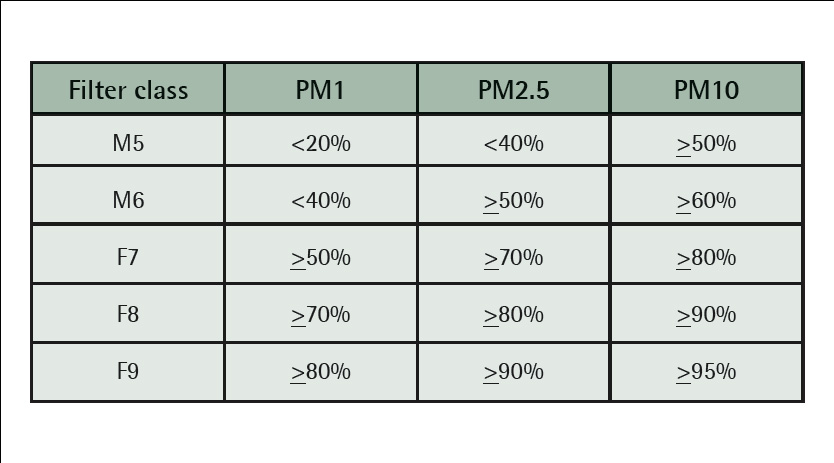

ISO 16890 is the international standard for filtration efficiency. This standard classifies the filter selection based on its performance against different particulate ranges. ISO 16890 classifies the performance of air filters into four main classifications ePM1, ePM2.5, ePM10 & ePM Coarse filters. The ISO 16890 standard has replaced the EN779:2012 for European filter classification, while for North America, ASHRAE 52.2 is still the widely used standard.

Typical efficiencies of air filters against PM1 and other fine dust mass concentrations.

Selection standard: Eurovent 4/23

The initial version of Eurovent 4/23 was created in 2017, followed by subsequent updates in 2018 and 2020. This standard provides explicit instructions on the appropriate filtration efficiency to select for various commercial and industrial purposes within a building.

Energy consumption and filter

The air filter itself does not consume energy; the HVAC system’s fan consumes energy. However, the filter can cause a pressure drop within the system, increasing the fan’s workload to maintain proper air volume. While the filter can contribute up to 30 percent of the HVAC system’s total energy consumption, it is a replaceable component that requires regular maintenance. Therefore, a filter with a long lifespan and low energy consumption can significantly impact the overall cost of owning and operating an HVAC system.

Energy consumption standard: Eurovent 4/21

A new energy rating system was introduced in 2014 to account for the significant proportion of energy costs attributed to air filters in an HVAC system. This rating system was updated to include ISO 16890 classifications, which group filters based on their efficiency. Their direct impact on energy consumption determines the energy rating for filters and ranges from A+ to E.

Energy rating

Each filter tested and certified according to the Eurovent 4/21 standard is required to display an energy rating on its packaging. The label includes a standard design for all Eurovent-tested air filters, highlighting the filter’s filtration efficiency, annual energy consumption, and rating. This makes it easy to compare different filter options quickly and effectively.

HEPA air purifiers – Utilisation with energy savings

HEPA air purifiers are commonly used as an additional measure alongside a building’s ventilation system. Their primary function is to increase the frequency of air changes while simultaneously removing airborne pollutants at their source. HEPA air purifiers are suitable for various settings where effective air filtration is required. In situations where sufficient air changes cannot be achieved, these purifiers can supplement the existing ventilation system without compromising the energy consumption of the HVAC system. In high-occupancy buildings, the risk of airborne contamination is greater, but using HEPA air purifiers can help reduce this risk by eliminating pollutants at their source.

Additionally, in facilities that use equipment or processes that produce low to moderate levels of particulate or molecular contaminants, HEPA air purifiers can provide added protection against airborne pollutants, including viruses, by maintaining low indoor particulate concentrations.

Energy-efficient air purification systems

Employing plug-and-play HEPA air purifiers throughout a building may increase energy consumption. To mitigate this, using these systems only when necessary is recommended. This can be achieved by integrating air quality sensors with HEPA air purifiers, ensuring the systems are activated based on building activities. By correlating operational activity with particulate levels, the use of air purifiers can be optimised.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.