In the quest to protect food, industry players are looking for solutions to keep food quality intact until it

reaches the end consumer. Consequently, the cold chain industry is diversifying into inhibiting the over-

ripening of fruits and vegetables.

The Indian food processing industry is one of the nation’s largest sectors in production, growth, potential consumption and export. As per the IMARC report, the country is the largest producer of milk in the world and the second largest in producing fruits and vegetables. Along with this, India also leads in the production of meat and seafood. Despite the production of food on such a large scale, it still needs to be made available to a substantial population. Food wastage across the supply chain can be considered a major reason behind the unavailability of food. Some estimates suggest up to 25 percent of our Food products get wasted at various stages for multiple reasons.

An immense quantity of food is wasted due to spoilage without a standard cold chain infrastructure. Hence, employing an efficient cold chain facility across the supply chain can play an instrumental role in preventing food from decaying. It is well- equipped with integrated refrigerated transport, pack houses, collection centres, and cold storage that can sustain large-scale food production and processing while simultaneously checking food waste. This is driving the demand for robust cold chain facilities in the country owing to the surging preference for fresh, locally produced, and preserved food. In addition, even the pharmaceutical segment has entered the league that requires efficient storage systems. All the factors together give the desired impetus to the growth of the cold chain at a phenomenal rate. The pandemic further propelled the need for facilities to efficiently store food products and ensure a seamless supply chain within the country and even overseas.

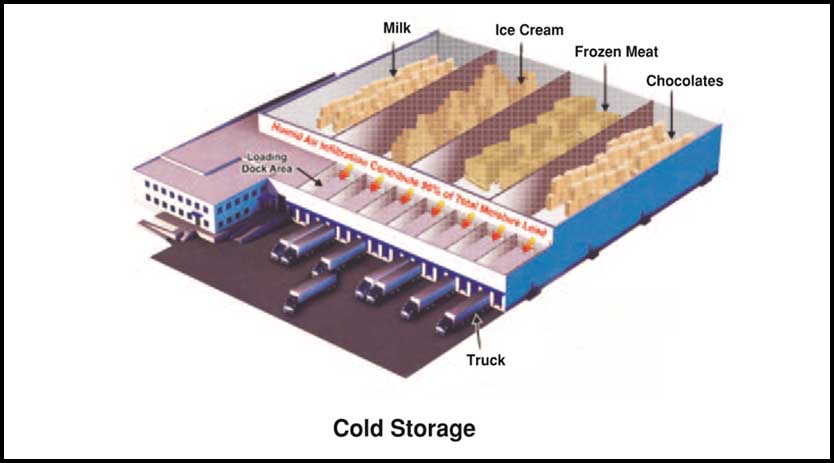

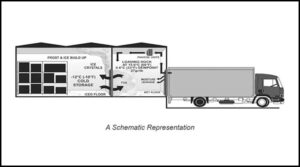

As the Indian food processing industry is poised to grow at a CAGR of 14.72 percent, according to the IMARC report for the forecasted period of 2022-2027, the country invariably seeks a resilient cold chain infrastructure. Here, it is essential to note that moisture is a significant deterrent in inhibiting the facility’s efficiency. Moisture has the potential to initiate a series of unwanted reactions that can lead to the spoilage of food. It gives rise to many problems entailing product frosting, slippery floors, building-up of ice on the conveyor belt, and cooling coils. It is also responsible for the formation of fog inside the loading dock.

Furthermore, there is a high probability of cardboard cartons becoming soft and undergoing sagging in the presence of moisture that can damage the products inside the box. Therefore, it is evident that humidity has the potential to incur a heavy loss to the cold chain sector in the form of reduced storage space, increased possibility of mould and mildew thriving in moisture, and added pressure to incorporate defrosting costs. It also accounts for reduced cooling efficiency due to water vapour loads and clogging in evaporator coils. Invariably all these factors can lead to frequent shutdowns, hampering the company’s profitability.

Hence, it is crucial to curtailing the moisture menace, and advanced dehumidification solutions are employed to elevate the productivity of cold chain facilities. It can curb frost formation on the evaporators and inhibit ice building up on the cooling coils. Considering that cold chains are developed sporadically with limited resources and infrastructure as and when the need arises, with the rising demand for quality food, it is more important to strengthen the cold chain infrastructure with robust dehumidification technology. Dehumidifiers can help achieve global safety and quality standards that increase the prospects of India becoming an international player as a quality food supplier.

In this quest to protect food, industry players are looking for solutions to keep food quality intact until it reaches the end consumer. To cater to this requirement, the cold chain industry is diversifying into inhibiting the over-ripening of fruits and vegetables. As ethylene is the major reason behind the over-ripening of fruits and vegetables, the Bry-Air Ethylene Scrubber (BES) extends the shelf life of fruits and vegetables with the help of continuous ethylene removal from the air being emitted by Fruits & Vegetables. It contributes to minimising the loss due to decay and enables the availability of food throughout the season. In the process, it also eliminates the use of harmful preservatives.

Considering the large scale at which the cold chain is required, industry players also seek energy- efficient technology to eliminate moisture. Here, desiccant dehumidification is the ideal solution for the most economical and energy-efficient solution for inhibiting food spoilage due to moisture in the cold chain. It is adept at providing dry air continuously, irrespective of the surrounding conditions. It is the way forward in getting better produce value and increasing the country’s global trade.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.