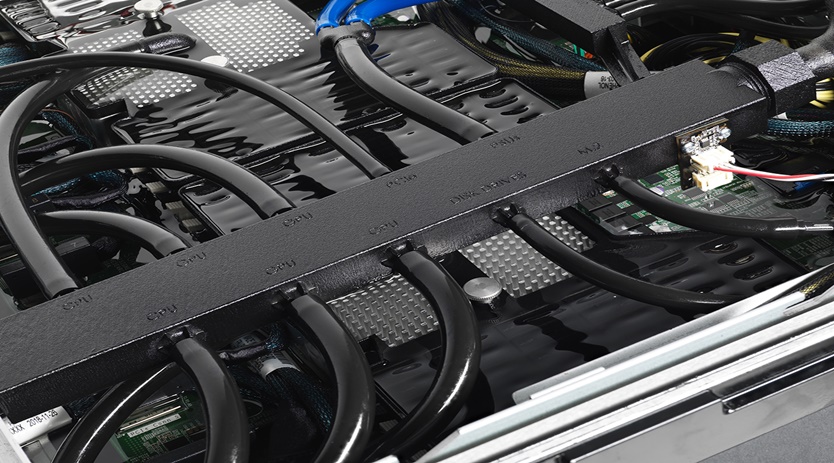

Precision immersion cooling offers a sealed chassis where all the server components are cooled using precision delivery of dielectric coolant. The heat is captured using a gentle recirculating coolant flow inside the chassis and transferred to a building circuit via a plate heat exchanger where it is rejected to ambient using dry-coolers; or reused for heating.

The chassis-level precision immersion cooling solution by Iceotope removes the heat from every part of the system reliably and efficiently. Precision delivery of dielectric coolant mitigates the need to constrain the design of the IT solution while maximising the cooling directly to the hotspots. This means there are no performance-throttling hotspots, front-to-back air cooling, or bottom-to-top immersion constraints.

Precision immersion cooling offers significant benefits in simplicity, cost, heat capture, and energy efficiency. While these advantages are tangible and measurable, design constraints will likely be imposed on the IT design with possible performance limitations depending on the solution provider. Iceotope’s precision immersion cooling solutions lower costs, improve efficiency, and increase density at scale. There are many benefits of choosing chassis-level precision immersion cooling over traditional air cooling and alternative liquid cooling options.

For more info visit: www.iceotope.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.